Nickel Round Bar

- Home

- Nickel Round Bar

Manufacturer of Nickel Alloy Rod, Check Pure Nickel Flat Bar Dimensions

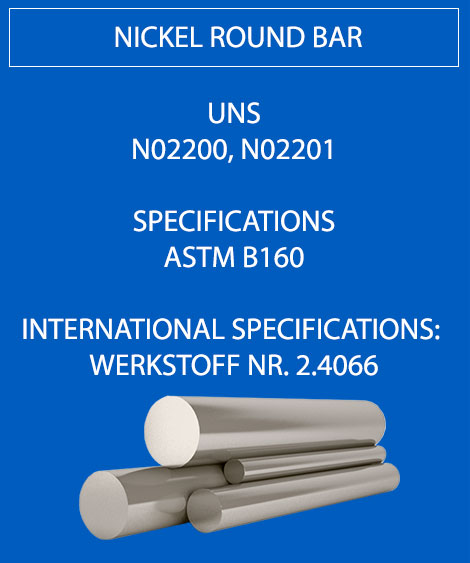

The ASTM B160 is a specification which covers nickel i.e. UNS N02200, low carbon nickel or as referred to as UNS N02201, and solution strengthened nickel which is known as UNS N02211. Typically, the specification covers these alloys produced in the form of hot worked, cold worked, or annealed condition bars. Furthermore, the ASTM B160 specification encompasses Nickel Alloy Rod and bars of varying shapes such as round, square, hexagonal, or rectangular solid section.

Nickel Round Bar

Nickel Alloy Rod

Pure Nickel Flat bar

Check Nickel Rectangular Bar Dimension & Sizes, Largest Nickel Alloy Bar stockist, Global Suppliers of Nickel Hex Bar.

Mechanical requirements of the ASTM B160 Nickel Round Bars include tensile strength, yield strength, as well as elongation parameters are given for specific conditions. Apart from these values, the specification of the round or ASTM B160 Nickel Rectangular Bar mentioned the dimensions i.e. diameter or distance between parallel surfaces. In addition to the mechanical requirements, the various test needs to be performed on the Nickel Round Bar.

Table of Content

- What is Nickel Round Bar?

- Pure Nickel Round Bar Price Per Kg

- Pure Nickel Round Bar Specification Chart

- Most famous types of Pure Nickel Alloy Round Bar

- Standard lengths of Nickel Round Bar

- Chemical Analysis of Nickel Alloy Bar

- Mechanical Behaviour of Pure Nickel Round Bar

- Pure Nickel Alloy Round Bar Condition

This being said, the Nickel Hex Bar is to undergo Chemical analysis, along with tension test, and hardness test. Pure Nickel Flat bar has, in addition, other remarkable properties such as good thermal, electrical and magnetostrictive properties. The high thermal conductivity of the Nickel Alloy Bar has to lead to the alloy being frequently used for heat exchangers.

| Pure Nickel Round bar size | Diameter: 3-~800mm |

|---|---|

| Pure Nickel Alloy Hex Bar size | 2-100mm A/F |

| Nickel Alloy Flat bar size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| Nickel Steel Square bar size | 4 to 100mm |

| Nickel Steel Angle bar size (in mm) | 3*20*20~12*100*100 |

| Pure Nickel Section | 3.0 to 12.0mm thickness |

| Nickel Channel Bar (in mm) | 80 x 40 to 150 x 75 section; 5.0 to 6.0 thickness |

| Pure Nickel Alloy Hollow Bar (in mm) | 32 OD x 16 ID to 250 OD x 200 ID) |

| Nickel Alloy Billet Size | 1/2" to 495mm Diameter |

| Nickel Rectangles Size | 33 x 30mm to 295 x 1066mm |

| Pure Nickel Alloy Round Bar Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Nickel Alloy Round Bar Surface | Bright, Hot Rolled Pickled, Cold Drawn, Sand Blasting Finished, Polished, Hairline |

| Nickel Round Bar Condition | Hardened & tempered, annealed |

Buy directly from ASTM B160 Nickel Round Bars Stockist, Contact us today to check availability of Nickel Bright Bar, Fast and cost-effective Nickel Alloy Forged Bars, Largest Independent Stockholder Nickel Square Bar

| Nickel Round Bar | Nickel Steel Flat Bar |

| Pure Nickel Bar | Nickel Alloy Flat Bar Black |

| Pure Nickel Alloy Rounds | Nickel Steel Flat Bar Bright |

| Nickel Alloy Bright Bar | Pure Nickel Flat Bar Polished |

| Nickel Steel Rods | Pure Nickel Flat Bar Cold Drawn |

| Pure Nickel Alloy Square Bar Cold Drawn | Pure Nickel Bright Bar material |

| Nickel Steel Rod | Nickel Flat Bar Annealed |

| Pure Nickel Round Bars | Pure Nickel Flat Bar stock |

| Nickel Hex Bar | Pure Nickel Alloy Threaded Bar |

| Pure Nickel Square Bar Polished | Nickel Bright Bar Hot Rolled |

| Nickel Alloy Hex Bar Bright | Nickel Steel Hollow Bar |

| Pure Nickel Alloy Rectangular Bar Annealed | Nickel Alloy Polished Hex Bar |

| Nickel Hex Bar Polished | Nickel Steel Hexagonal Bar |

| Nickel Alloy Rectangular Bar | Nickel Threaded Bar Black |

| Nickel Alloy Hex Bar Annealed | Nickel Cold Drawn Round Bar |

| Nickel Steel Forged Bar | Pure Nickel Alloy Polished Bar |

Specialise in distributing Nickel Threaded Bar, Get a Quote from Pure Nickel Polished Bar stockholder. Ask free sample of Nickel Alloy Round Bars. largest independent Supplier Nickel Alloy Black Bar, Order custom sizes of Hot Rolled Nickel Round Bar online

| 5.0 mm | 45.0 mm |

| 6.0 mm | 50.0 mm |

| 7.0 mm | 55.0 mm |

| 8.0 mm | 60.0 mm |

| 9.0 mm | 65.0 mm |

| 10.0 mm | 70.0 mm |

| 12.0 mm | 75.0 mm |

| 16.0 mm | 80.0 mm |

| 20.0 mm | 90.0 mm |

| 25.0 mm | 100.0 mm |

| 30.0 mm | 130.0 mm |

| 35.0 mm | 160.0 mm |

| 40.0 mm | 200.0 mm |

Types of Nickel Polished Bar

Nickel Steel Rod

Pure Nickel Round Bars

Nickel Polished Hex Bar

Nickel Cold Drawn Round Bar

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 8.9 G/Cm3 | 1446 °C (2635 °F) | Psi – 67000 , MPa – 462 | Psi – 21500 , MPa – 148 | 45 % |

| Grade | Ni | Fe | C | Mn | Si | Cu | Mg | Ti | S |

|---|---|---|---|---|---|---|---|---|---|

| Nickel 201 | 99.0 Min | 0.4 Max | 0.02 Max | 0.35 Max | 0.2 Max | 0.25 Max | 0.15 Max | 0.1 Max | 0.01 Max |

| Nickel 200 | 99.0 Min | 0.4 Max | 0.15 Max | 0.35 Max | 0.1 Max | 0.25 Max | - | - | 0.01 Max |

Suppliers and Stockists of ASTM B160 Nickel Alloy Threaded Bar, Check Availability of Nickel Alloy Flat Bar, Top-notch Manufacturer of ASTM B160 Nickel Hex Bar, Exporter of Nickel Triangular Bars. Most reliable Distributor of Nickel Alloy Bright Bar, Nickel Alloy Threaded Bar.

| H&T | Hardened and tempered. |

| ANN | Annealed |

| PH | Precipitation hardened. |