ASTM B564 Flange

- Home

- ASTM B564 Flange

ASME SB564 Forged Fittings Manufacturer, Check ASTM B564 Nickel Alloy Forgings Dimensions

The ASTM B564 is a specification which covers nickel alloy forged fittings, flanges and forgings products. These asme sb564 forged fittings consist of various components such as elbows, flanges etc. As required by the ASTM B564 specification, the alloys that fall under the nickel based category can be segregated into different grades, which in turn will depend on their chemical composition. A chemical analysis shall be employed on each alloy component viz. astm b564 socket weld fittings.

ASTM B564 Flange

ASME SB564 Forged Fittings

ASTM B564 Pipe Flange

Looking to Buy ASTM B564 Slip On Flange from Suppliers, Check ASME SB564 Forged Fittings Dimensions & Weight charts, Ask For ready stock of B564 Threaded Elbow.

Many manufacturers prefer conducting a chemical analysis in order to determine the chemical composition of the alloy used to produce the astm b564 forged fittings. Including the Grain size of the alloy, the mechanical properties of the astm b564 flange such as its tensile strength, yield strength, and elongation is to be calculated according to the specification. In addition, a tension test and a nondestructive ultrasonic test too have to be singularly performed on each specimen i.e.the asme sb564 flange.

Table of Content

- What is ASTM B564 Flange?

- ASME SB564 Flange Price List

- Specification Chart of ASTM B564 Flange

- ASTM B564 Nickel Alloy Flanges & Forgings Equivalent Grades

- Class 150 SB564 Flange Dimensions

- Approximate Masses & Dimensions of ASME B16.5 ASME SB564 Flange

- Ready Stock of ASTM B564 Nickel Alloy Forgings

- Types of ASME SB564 Flange

- Weight Chart Of ASTM B564 Flange

Used for pipes with small diameters, a b564 threaded elbow permits flexibility in the change of the direction of the flow, as required by the buyer or the more conventionally used 45 degrees, 90 degrees or 22.5 degrees. b564 pipe flange is a component in which pipes, valves, pumps as well as other equipment are connected to form a piping system.

| ASME SB564 Flange Size Chart | 1/2" (15 NB) to 48" (1200NB) DN10~DN5000 |

|---|---|

| B564 SORF Flange Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| ASTM B564 Flange Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| ASTM B564 Flange Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| ASME SB564 Flange JIS | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K |

| ASME SB564 Flange UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

| B564 FlangeEN | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Most common types of SB564 Flange | Forged / Threaded / Screwed / Plate |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| ASTM B564 Flange Production technique |

|

| B564 Flange Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Special design |

As per your drawing AS, ANSI, BS, DIN and JIS |

| ASTM B564 Flange Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

Leading B564 Pipe Flange Stockist, Check available sizes of ASTM B564 Socket Weld Fittings, Get a best quote for ASTM B564 Weld Neck Flange from leading manufacturers, We have Global sales network for ASME SB564 Threaded Fittings

| Nominal Size |

Outside Diameter

(OD) |

Min. Thickness

(T) |

RF Dia.

(R) |

No. of Bolt Holes | Diameter of Holes |

Bolt Circle

(BC) |

SO Bore ID

(SB) |

WN Bore ID

(WB) |

Dia. Hub Base

(HB) |

Dia. of Hub Top

(HT) |

SO LTH

(SL) |

WN LTH

(WL) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1⁄2 | 3.50 | 0.38 | 1.38 | 4 | 0.62 | 2.38 | 0.88 | 0.62 | 1.19 | 0.84 | 0.56 | 1.81 |

| 3⁄4 | 3.88 | 0.44 | 1.69 | 4 | 0.62 | 2.75 | 1.09 | 0.82 | 1.50 | 1.05 | 0.56 | 2.00 |

| 1 | 4.25 | 0.50 | 2.00 | 4 | 0.62 | 3.12 | 1.36 | 1.05 | 1.94 | 1.32 | 0.62 | 2.12 |

| 11⁄4 | 4.62 | 0.56 | 2.50 | 4 | 0.62 | 3.50 | 1.70 | 1.38 | 2.31 | 1.66 | 0.75 | 2.19 |

| 11⁄2 | 5.00 | 0.62 | 2.88 | 4 | 0.62 | 3.88 | 1.95 | 1.61 | 2.56 | 1.90 | 0.81 | 2.38 |

| 2 | 6.00 | 0.69 | 3.62 | 4 | 0.75 | 4.75 | 2.44 | 2.07 | 3.06 | 2.38 | 0.94 | 2.44 |

| 21⁄2 | 7.00 | 0.81 | 4.12 | 4 | 0.75 | 5.50 | 2.94 | 2.47 | 3.56 | 2.88 | 1.06 | 2.69 |

| 3 | 7.50 | 0.88 | 5.00 | 4 | 0.75 | 6.00 | 3.57 | 3.07 | 4.25 | 3.50 | 1.12 | 2.69 |

| 31⁄2 | 8.50 | 0.88 | 5.50 | 8 | 0.75 | 7.00 | 4.07 | 3.55 | 4.81 | 4.00 | 1.19 | 2.75 |

| 4 | 9.00 | 0.88 | 6.19 | 8 | 0.75 | 7.50 | 4.57 | 4.03 | 5.31 | 4.50 | 1.25 | 2.94 |

| 5 | 10.00 | 0.88 | 7.31 | 8 | 0.88 | 8.50 | 5.66 | 5.05 | 6.44 | 5.56 | 1.38 | 3.44 |

| 6 | 11.00 | 0.94 | 8.50 | 8 | 0.88 | 9.50 | 6.72 | 6.07 | 7.56 | 6.63 | 1.50 | 3.44 |

| 8 | 13.50 | 1.06 | 10.62 | 8 | 0.88 | 11.75 | 8.72 | 7.98 | 9.69 | 8.63 | 1.69 | 3.94 |

| 10 | 16.00 | 1.12 | 12.75 | 12 | 1.00 | 14.25 | 10.88 | 10.02 | 12.00 | 10.75 | 1.88 | 3.94 |

| 12 | 19.00 | 1.19 | 15.00 | 12 | 1.00 | 17.00 | 12.88 | 12.00 | 14.38 | 12.75 | 2.12 | 4.44 |

| 14 | 21.00 | 1.31 | 16.25 | 12 | 1.12 | 18.75 | 14.14 | 13.25 | 15.75 | 14.00 | 2.19 | 4.94 |

| 16 | 23.50 | 1.38 | 18.50 | 16 | 1.12 | 21.25 | 16.16 | 15.25 | 18.00 | 16.00 | 2.44 | 4.94 |

| 18 | 25.00 | 1.50 | 21.00 | 16 | 1.25 | 22.75 | 18.18 | 17.25 | 19.88 | 18.00 | 2.62 | 5.44 |

| 20 | 27.50 | 1.62 | 23.00 | 20 | 1.25 | 25.00 | 20.20 | 19.25 | 22.00 | 20.00 | 2.81 | 5.62 |

| 22 | 29.50 | 1.75 | 25.25 | 20 | 1.38 | 27.25 | 22.22 | 21.25 | 24.25 | 22.00 | 3.07 | 5.82 |

| 24 | 32.00 | 1.81 | 27.25 | 20 | 1.38 | 29.50 | 24.25 | 23.25 | 26.12 | 24.00 | 3.19 | 5.94 |

| ANSI, ASME, ASA, B16.5 150lb/sq.in. WELDING NECK FLANGE RF | |||||||||||

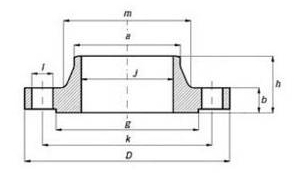

| ø | D | b | g | m | a | J* | h | k | Holes | l | Kg. |

| 1/2″ | 88,9 | 11,1 | 34,9 | 30,2 | 21,3 | 15,7 | 47,6 | 60,3 | 4 | 15,9 | 0,500 |

| 3/4″ | 98,4 | 12,7 | 42,9 | 38,1 | 26,7 | 20,8 | 52,4 | 69,8 | 4 | 15,9 | 0,700 |

| 1″ | 107,9 | 14,3 | 50,8 | 49,2 | 33,5 | 26,7 | 55,6 | 79,4 | 4 | 15,9 | 1,100 |

| 1 1/4″ | 117,5 | 15,9 | 63,5 | 58,8 | 42,2 | 35,1 | 57,1 | 88,9 | 4 | 15,9 | 1,500 |

| 1 1/2″ | 127,0 | 17,5 | 73,0 | 65,1 | 48,3 | 40,9 | 61,9 | 98,4 | 4 | 15,9 | 1,800 |

| 2″ | 152,4 | 19,0 | 92,1 | 77,8 | 60,3 | 52,6 | 63,5 | 120,6 | 4 | 19,0 | 2,700 |

| 2 1/2″ | 177,8 | 22,2 | 104,8 | 90,5 | 73,1 | 62,7 | 69,8 | 139,7 | 4 | 19,0 | 4,400 |

| 3″ | 190,5 | 23,8 | 127,0 | 107,9 | 88,9 | 78,0 | 69,8 | 152,4 | 4 | 19,0 | 5,200 |

| 3 1/2″ | 215,9 | 23,8 | 139,7 | 122,2 | 101,6 | 90,2 | 71,4 | 177,8 | 8 | 19,0 | 6,400 |

| 4″ | 228,6 | 23,8 | 157,2 | 134,9 | 114,3 | 102,4 | 76,2 | 190,5 | 8 | 19,0 | 7,500 |

| 5″ | 254,0 | 23,8 | 185,7 | 163,5 | 141,2 | 128,3 | 88,9 | 215,9 | 8 | 22,2 | 9,200 |

| 6″ | 279,4 | 25,4 | 215,9 | 192,1 | 168,4 | 154,2 | 88,9 | 241,3 | 8 | 22,2 | 11,000 |

| 8″ | 342,9 | 28,6 | 269,9 | 246,1 | 219,1 | 202,7 | 101,6 | 298,4 | 8 | 22,2 | 18,300 |

| 10″ | 406,4 | 30,2 | 323,8 | 304,8 | 273,0 | 254,5 | 101,6 | 361,9 | 12 | 25,4 | 25,000 |

| 12″ | 482,6 | 31,7 | 381,0 | 365,1 | 323,8 | 304,8 | 114,3 | 431,8 | 12 | 25,4 | 39,000 |

| 14″ | 533,4 | 34,9 | 412,7 | 400,0 | 355,6 | 336,5 | 127,0 | 476,2 | 12 | 28,6 | 51,000 |

| 16″ | 596,9 | 36,5 | 469,9 | 457,2 | 406,4 | 387,3 | 127,0 | 539,7 | 16 | 28,6 | 60,000 |

| 18″ | 635,0 | 39,7 | 533,4 | 504,8 | 457,2 | 438,1 | 139,7 | 577,8 | 16 | 31,7 | 71,000 |

| 20″ | 698,5 | 42,9 | 584,2 | 558,8 | 508,0 | 488,9 | 144,5 | 635,0 | 20 | 31,7 | 88,000 |

| 22″ | 749,3 | 46,0 | 641,2 | 609,6 | 558,8 | 539,7 | 149,2 | 692,1 | 20 | 34,9 | 102,000 |

| 24″ | 812,8 | 47,6 | 692,1 | 663,6 | 609,6 | 590,5 | 152,4 | 749,3 | 20 | 34,9 | 119,000 |

| * |

The data “J” corresponds to the STD schedule NOTE: 1. Class 150 flanges except Lap Joint will be furnished with 0.06 (1.6mm) raised face, which is included in ‘Thickness’ (C) and ‘Length through Hub’ (Y1), (Y3). 2. For Slip-on, Threaded, Socket Welding and Lap Joint Flanges, the hubs can be shaped either vertical from base to top or tapered within the limits of 7 degrees. 3. Blind Flanges may be made with the same hub as that used for Slip-on Flanges or without hub. 4. The gasket surface and backside (bearing surface for bolting) are made parallel within 1 degree. To accomplish parallelism, spot facing is carried out according to MSS SP-9, without reducing thickness (C). 5. Depth of Socket (D) is covered by ANSI B 16.5 only in sizes through 3 inch, over 3 inch is at the manufacturer’s option. 6. Welding Neck Flange Bore Size SCH10, SCH20, SCH30, STD, SCH40, SCH60, SCH80, SCH100, SCH 120, SCH140, SCH160, XS |

||||||||||

ASME B16.5 ASME SB564 Welding Neck Flange T&G 1-1/4″ SCH160 2500#

ASME SB564 Threaded Fittings

ASTM B564 Slip on Raised Face Flange

ASME B16.5 ASTM B564 SORF Flange 2″ SCH100 150#

ASME SB564 Spectacle Blind Flange

ASME B16.5 ASTM B564 Weld Neck Ring-type Joint Flange DN80 SCH40S Class900

ASME B16.5 SB564 Blind Flange Raised Face DN250 Class 150

ASME B16.5 B564 Blind Flange RF 3 Inch Class150

ASME B16.5 ASTM B564 WN RF Flange 2″ SCH100 150#

SB564 Threaded Socket Weld Flange

SB564 EN 1092-1 Flanges

ANSI B16.5 ASTM B564 WN RF Flange DN200 SCH80S CL600

ANSI B16.5 ASTM B564 EN 1.4562 Welding Neck Flange Raised Face 1-1/4 Inch Sch40S 300#

ASTM B564 Socket Weld Fittings

B564 Flat Face Blind Flange

ASME B16.5 ASTM B564 Welding Neck Flange Raised Face 6 Inch Sch40S 300#

| ASME SB564 Flange | ASTM B564 Blind Flange |

| B564 Slip on Flange | ASME SB564 Threaded Flange |

| ASME SB564 Reducing Flange | SB564 Socket Weld Flange |

| ASME SB564 Weld Neck Flanges | ASTM B564 Lap Joint Flanges |

| ASME SB564 Long Weld Neck Flanges | ASME SB564 Spectacle Blind Flanges |

| ASME SB564 Spades & Ring Spacers | SB564 Nipoflange |

| ASTM B564 5D Weldoflange | ASTM B564 Flange Outlet |

| ASME SB564 Forged Flanges | B564 Plate Flange |

| ASME SB564 Ring Type Joint Flanges | SB564 Raised Face Flanges |

| ASTM B564 Tongue and Groove Flanges | B564 Male and Female Flange |

| ASME SB564 Reducing Flanges | ASME SB564 ASME B16.5 Flanges |

| ASTM B564 Flanges | B564 BS 10 Flanges |

| ASTM B564 BS 4504 Flanges | SB564 EN 1092-1 Flanges |

| ASME SB564 SORF Flange | ASME SB564 BLRF Flange |

| ASTM B564 WNRF Flange | B564 RTJ Flange |

| ASTM B564 Series a Lap Joint Ring Flange | SB564 Class 300 threaded flange |

| ASME SB564 PN16 blind flange | ASTM B564 Forged Socket Weld Pipe Flange |

| ASTM B564 Class 300 slip on flange | ASME SB564 Slip On Weld Flange |

| B564 Forged steel slip on flanges | B564 Race face slip on flange |

| ASTM B564 SWRF Flange | ASTM B564 Forged blind flange |

| ASTM B564 groove weld neck flange | ASME SB564 Socket Weld Hub Flange |

| ASTM B564 threaded lap joint flange | ASTM B564 Slip On Integral flange |

| ASTM B564 Forged integral puddle flange | B564 table e long weld neck |

| ASME SB564 Class 150 LBS Flange | B564 PN10 Forged Flanges |

| ASTM B564 RTJ Flanges | ASME SB564 PN10 Plate Flanges |

| ASME SB564 Tongue & Groove Flanges | ASTM B564 Reducing Flanges |

| B564 Class 150 reducing threaded flange | B564 Class 150 Pipe Flange |

| ASME SB564 Class 150 Flange | ASTM B564 Pipe Flanges |

| ASME SB564 BS 10 Flanges | SB564 Class 150 Tongue & Groove Flanges |

| B564 BS 4504 pn16 flange | ASME SB564 EN 1092-1 flat flange |

| ASTM B564 Raised Face Flanges | ASME SB564 Flat Faced Plate Flanges |

| SB564 Bleed Rings | ASME SB564 Class 150 Weldoflange |

| B564 Class 150 LBS Nipo Flange | ASME SB564 Long Weld Neck Flanges |

| ASME SB564 Lap Joint Pipe Flanges | ASME SB564 PN16 Screwed Flanges |

Our SB564 Blind Flange are very cost-effective, Ask free sample of ASTM B564 WNRF Flange. Purchase ASME SB564 Fittings at reasonable price. Top-notch stockist of ASTM B564 SWRF Flage, SB564 Reducing Flange widely used in Chemical Industry

Exclusive Ready Stock of ASTM B564 Flange

ASTM B564 RTJ Flanges

B564 Class 150 LBS Nipo Flange

ASTM B564 Class 300 slip on flange

ASME SB564 PN16 Screwed Flanges

Largest supplier of small-quantity ASTM B564 Socket Weld Elbow, Best Price & Fast Delivery for ASME SB564 SORF Flange, Own stockyard of SB564 Threaded Flange, Largest Manufacturer B564 Weldo Flange. ASTM B564 Flange, Contact us today to buy ASME SB564 Threaded Union at 10% discounted rate.

|

Standard |

Class |

Diameter |

Bolt Circle Diameter |

Number of Bolts |

Bolt Size |

Diameter of Bolt Hole |

|---|---|---|---|---|---|---|

|

AS4087 Flanges |

PN14 Flanges |

95 |

67 |

4 |

M12 |

14 |

|

AS 2129 Flange

|

Table C Flanges |

95 |

67 |

4 |

13 |

14 |

|

Table D Flanges |

95 |

67 |

4 |

13 |

14 |

|

|

Table E Flanges |

95 |

67 |

4 |

13 |

14 |

|

|

Table F Flanges |

95 |

67 |

4 |

13 |

14 |

|

|

Table H Flanges |

114 |

83 |

4 |

16 |

17 |

|

|

Table J Flanges |

114 |

83 |

4 |

16 |

17 |

|

|

ANSI B16.5 Flanges

|

ANSI 150 Flanges |

89 |

60 |

4 |

13 |

16 |

|

ANSI 300 Flanges |

95 |

67 |

4 |

13 |

16 |

|

|

ANSI 600 Flanges |

95 |

67 |

4 |

13 |

16 |

|

|

ANSI 900 Flanges |

121 |

83 |

4 |

19 |

22 |

|

|

ANSI 1500 Flanges |

121 |

83 |

4 |

19 |

22 |

|

|

ISO 7005 (DIN) Flange

|

PN6 Flanges |

80 |

55 |

4 |

M10 |

11 |

|

PN10 Flanges |

95 |

65 |

4 |

M12 |

14 |

|

|

PN16 Flanges |

95 |

65 |

4 |

M12 |

14 |

|

|

PN20 Flanges |

90 |

60.5 |

4 |

M14 |

16 |

|

|

PN25 Flanges |

95 |

65 |

4 |

M12 |

14 |

|

|

PN40 Flanges |

95 |

65 |

4 |

M12 |

14 |