Monel K500 Pipe Fittings

- Home

- Monel K500 Pipe Fittings

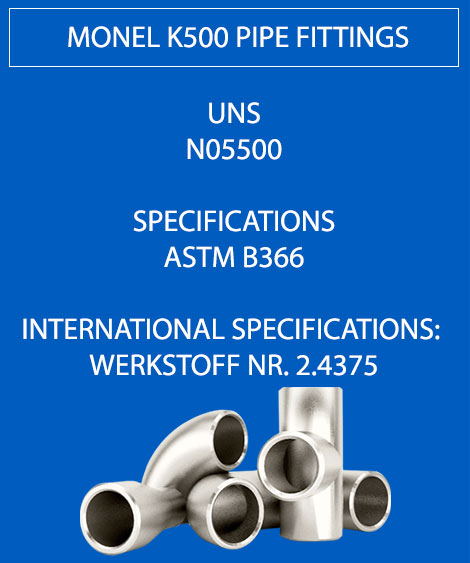

Alloy K500 Stub End Manufacturer, View ASTM B366 UNS N05500 Reducing Elbow Dimensions/ Weight Chart

The tensile strength properties of this nickel based Monel K500 Pipe fittings can be maintained to an elevated temperature setting to about 1200° F. However, the properties of Monel 500 such as ductility and toughness are maintained down to a temperature of about 400° F. This nickel based Monel K500 Stub End tends to not only be spark resistant but is also non-magnetic to a temperature as low as about -200° F. Hence, these fittings can be used in applications where magnetism is not a mandate.

Monel K500 Pipe Fittings

Alloy K500 Stub End

ASTM B366 UNS N05500 Reducing Elbow

Global Suppliers of Monel K500 Pipe Cap, Buy Certified & Tested Monel K500 Elbow, Check Monel K500 Fittings Price List.

However, if the application requires magnetic properties, it is possible to establish a magnetic layer on the surface of the Alloy K500 Pipe Fittings during its processing. Aluminium and copper are two elements that could be fastidiously oxidized during the heating process, thus, leaving a magnetic nickel rich film on the surface of Monel K500 Pipe Cap. In order to remove this magnetic film around these Monel K500 Fittings and to restore back its non-magnetic properties, the alloy can be pickled or bright dipped in acid.

Table of Content

- What is Alloy Monel K500 Fittings?

- Price List of Alloy Monel K500 Pipe Fittings

- Material Specification of Monel K500 Pipe Fittings

- Most popular types of Monel K500 Fittings

- Weight Chart & Dimensions of ASTM B366 UNS N05500 Tee

- Monel grade K500 Pipe Fittings Physical Properties

- Chemical Structure of Monel Alloy K500 Buttweld Fittings

- Nickel K500 Fittings Material Equivalent

- Thermal Properties of Monel 2.4375 Fittings

Monel K-500 fittings, for e.g. Monel K500 Elbow have been found to be particularly resistant to a sour-gas environment, which is why they are often seen in applications involving sour wells. The amalgamation of very low corrosion rates in high-velocity seawater along with high tensile strength makes the Monel K500 Tee well suited for to be used in marine service. Although fouling could occur followed by pitting in the presence of stagnant or slow-moving seawater. But this pitting generally slows down after being fairly rapid attack initially.

| Specifications : ASTM B 366 / ASME SB 366 |

| Dimensions : ANSI/ASME B16.9, B16.28, MSS-SP-43. |

| Range : Seamless Butt Weld Fittings: 1/2" – 10", Welded Butt Weld Fittings: 1/2" – 48" |

| Types : Seamless / Welded / Fabricated |

| Schedule : Sch 5 TO Sch XXS. |

| Grade : Monel 500 (UNS No. N05500) |

Most recognized Monel K500 Tee Manufacturer, Buy Saudi Aramco approved Alloy K500 Pipe Fittings, Global stockist of Monel K500 Stub End, Ask free sample of Alloy K500 Fittings

| Alloy Monel K500 Fittings | Monel K500 Pipe Fitting |

| Nickel Alloy K500 90 Degree Elbow | Monel grade K500 End Cap |

| Monel 2.4375 45 Degree Elbow | Monel Alloy K500 Buttweld Fitting |

| Monel K500 UNS N05500 1D Elbow | Nickel K500 Short Stub End |

| Monel Alloy K500 Stub End | Alloy Monel K500 Pipe Cap |

| ASTM B366 UNS N05500 3D Elbow | Alloy K500 End Cap |

| Monel K500 5D Elbow | Alloy K500 Reducer |

| Alloy K500 Buttweld Fittings | Alloy grade K500 Pipe Bend |

| DIN 2.4375 Pipe Fittings | UNS N05500 Long Stub End |

| Alloy K500 Eccentric Reducer | Alloy K500 UNS N05500 Long Radius Elbow |

| Alloy K500 Concentric Reducer | Nickel Alloy K500 Short Radius Elbow |

| Monel 2.4375 Equal Cross | Alloy Monel K500 Pipe Cap |

| Monel grade K500 Lateral Tee | ASTM B366 UNS N05500 Cross Tee |

| Nickel K500 Reducing Cross | Monel Alloy K500 Equal Cross |

| Alloy K500 Equal Tee | Alloy K500 Stub End |

| Alloy grade K500 Concentric Reducer | Nickel 2.4375 5D Elbow |

Largest distributor of small-quantity ASME SB366 Alloy K500 Long Stub End, Get a Quote of ASTM B366 UNS N05500 Buttweld Tee. Purchase Alloy K500 Short Radius Elbow at reasonable price. Fast Delivery and cost-effective rates for Monel DIN 2.4375 Cross, Accept all small/ Large Orders of Alloy K500 Equal Tee

Exclusive Ready Stock of Alloy K500 Fittings

Alloy Monel K500 Buttweld Fittings

Monel grade K500 Concentric Reducer

Monel 2.4375 Equal Cross

Monel K500 UNS N05500 Long Radius Elbow

| Nominal Pipe Size | Outside diameterat bevel | Center-to-End | |

|---|---|---|---|

| Run (C) | Outlet(M) | ||

| 1/2" | 21.3 | 25 | 25 |

| 3/4" | 26.7 | 29 | 29 |

| 1" | 33.4 | 38 | 38 |

| 1 1/4" | 42.2 | 48 | 48 |

| 1 1/2" | 48.3 | 57 | 57 |

| 2" | 60.3 | 64 | 64 |

| 2 1/2" | 73.0 | 76 | 76 |

| 3" | 88.9 | 86 | 86 |

| 3 1/2" | 101.6 | 95 | 95 |

| 4" | 114.3 | 105 | 105 |

| 5" | 141.3 | 124 | 124 |

| 6" | 168.3 | 143 | 143 |

| 8" | 219.1 | 178 | 178 |

| 10" | 273.0 | 216 | 216 |

| 12" | 323.8 | 254 | 254 |

| 14" | 355.6 | 279 | 279 |

| 16" | 406.4 | 305 | 305 |

| 18" | 457.0 | 343 | 343 |

| 20" | 508.0 | 381 | 381 |

| 22" | 559.0 | 419 | 419 |

| 24" | 610.0 | 432 | 432 |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Monel K500 | 8.44 g/cm3 | 1350 °C (2460 °F) | Psi – 160000 , MPa – 1100 | Psi – 115000 , MPa – 790 | 20 % |

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

| Monel K500 | 0.25 max | 1.5 max | 0.5 max | 0.010 max | 27.00 – 33.00 | 0.5 – 2 | 63.00 min |

| STANDARD | WERKSTOFF NR. | UNS |

| Monel K500 | 2.4375 | N05500 |

Delivering Monel UNS N05500 Seamless Pipe Fittings everywhere, Specialise in manufacturing Monel K500 Buttweld Fitting, Suppliers and Stockists of Monel DIN 2.4375 Pipe Stub, Traders of K500 Monel Alloy Reducer. Buy Monel K500 Lateral Tee, ASTM B366 K500 Monel End Cap directly from manufacturers.

|

Temperature, °F |

Mean

Linear Expansion, in/in-°F x 10(-6) |

Thermal

Conductility,(a) Btu-in-hr-sq ft-°F |

Special Heat,(a)Btu-lb-°F |

Electrical

Resistivity,(b) ohm-circ mil-ft |

|

-320 -200 70 200 400 600 800 1000 1200 1400 1600 1800 |

6.2 6.8 -- 7.6 8.1 8.3 8.5 8.7 9.1 9.3 9.6 -- |

-- 92 121 136 156 178 198 220 240 262 282 302* |

-- 0.077 0.100 0.107 0.114 0.117 0.120 0.125 0.132 0.141 0.157 0.186* |

-330.8(c) -- 370 372 378 385 390 393 396 400 408 418 |