Hastelloy C22 Pipe Fittings

- Home

- Hastelloy C22 Pipe Fittings

Check Alloy C22 Tee Dimensions, Purchase ASTM B366 UNS N06022 Stub End at Factory Price

According to the ASTM B366 specification Forging or shaping procedure to be performed by these nickel based fittings, in this case, Hastelloy C22 Stub End could be done singularly or by a combination of two or more operations. For instance, procedures that could be carried out on the Hastelloy C22 Pipe Fittings include bending, hammering, piercing, pressing, extruding, upsetting, rolling, as well as fusion welding. Aside from meeting the prearrange requisites such as tensile properties, tension test, heat treatment, and dimensions, the ASTM B366 UNS N06022 Stub end must also conform to the other prerequisites like the chemical composition which is to be checked by conducting a Chemical and product analysis of the same component.

Hastelloy C22 Pipe Fittings

Alloy C22 Tee

B366 UNS N06022 Stub end

Most trusted Hastelloy C22 Fittings Stockist. Check Price List of Hastelloy C22 Elbow, A long established Suppliers of Hastelloy C22 Reducer.

The Hastelloy C22 Elbow is a popular choice of fitting because it permits flexibility for change in direction of the flow of the media while having excellent corrosion resistance properties at the same time. In particular, the Hastelloy C22 Fittings demonstrates excellent resistance to oxidative media like ferric acids or acetic anhydride, containing environments as well as oxidizing aqueous media. The Hastelloy C22 Reducer is well received in the marine engineering industry as well where the alloy has resistance to brine and seawater as well.

Table of Content

- What is Hastelloy Alloy C22 Fittings?

- Price List of Hastelloy Alloy C22 Pipe Fittings

- Hastelloy C22 Pipe Fittings Specification Chart

- Different Types of Hastelloy C22 Fittings

- Weight Chart of Nickel Alloy C22 Reducer

- Mechanical Behaviour of Nickel C22 Pipe Fittings

- Composition Chart of ASTM B366 UNS N06022 Buttweld Fittings

- Equivalent grades of Hastelloy 2.4602 Fittings

- international Trade Names of C22 Hastelloy Fittings

- Hastelloy C22 Pipe Fittings Dimensions

The Alloy C22 Tee is a short pipe that is angled at 90 degrees, in a T-shape and aids in changing the direction like of the flow to 90 degrees while showing resistance to localized attack for eg. pitting, crevice corrosion in addition to SCC or stress related corrosion cracking.

| Hastelloy UNS N06022 Fittings Specifications | ASTM B366 / ASME SB366 |

|---|---|

| Nickel Alloy C22 Pipe Fittings size | Hastelloy C22 Seamless Butt Weld Fittings: 1/2" - 10" Hastelloy Alloy C22 Welded Butt Weld Fittings: 1/2" - 48" |

| Hastelloy C22 FittingsType | DN15-DN1200 |

| Hastelloy UNS N06022 Elbows | Angle : 22.5 deg, 30deg, 45 deg, 90 deg, 180 deg, 1.0D, 1.5D, 2.0D, 2.5D, 3D, 4D, 5D, 6D, 7D-40D . Standard: ASME B16.9, ASME B16.28, ASME B16.25, MSS SP-75 DIN2605 JISB2311 JISB2312 JISB2313, BS, GB, ISO |

| C22 Hastelloy Pipe Fittings Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 |

| Alloy C22 Fittings Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| Bending Radius | R= 2D, 6D, 1D, 5D, 8D, 3D, 10D or Custom Hastelloy DIN 2.4602 Pipe Fitting |

| Size Range | ½" NB to 24" NB in Sch 10s, 40s, 80s, 160s, XXS. (DN6~DN100) Nickel C22 Buttweld Fitting |

| ASTM B366 UNS N06022 Buttweld Fitting Connection | Welding |

| Hastelloy C22 Fittings Manufacturing process | Push, Press, Forge, Cast, etc. |

| We provide Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

Schedule 80 Hastelloy C22 Stub End Distributor, Get in touch for assistance before buying Alloy C22 Fittings, Purchase Alloy C22 Elbow at Factory Price, Check Availability of C22 Hastelloy Alloy End Cap

| Hastelloy Alloy C22 Fittings | Hastelloy C22 Pipe Fitting |

| Hastelloy DIN 2.4602 90 Degree Elbow | Nickel C22 End Cap |

| C22 Hastelloy 45 Degree Elbow | ASTM B366 UNS N06022 Buttweld Fitting |

| Alloy C22 1D Elbow | Hastelloy 2.4602 Short Stub End |

| ASTM B366 UNS N06022 Stub End | Hastelloy Alloy C22 Pipe Cap |

| Nickel Alloy C22 3D Elbow | Hastelloy UNS N06022 End Cap |

| Hastelloy C22 5D Elbow | Hastelloy UNS N06022 Reducer |

| Hastelloy Alloy C22 Buttweld Fittings | Nickel C22 Pipe Bend |

| C22 Hastelloy Pipe Fittings | Alloy C22 Long Stub End |

| ASTM B366 UNS N06022 Eccentric Reducer | Alloy C22 Long Radius Elbow |

| Hastelloy UNS N06022 Concentric Reducer | Hastelloy DIN 2.4602 Short Radius Elbow |

| C22 Hastelloy Equal Cross | Hastelloy Alloy C22 Pipe Cap |

| Nickel C22 Lateral Tee | Nickel Alloy C22 Cross Tee |

| Hastelloy 2.4602 Reducing Cross | ASTM B366 UNS N06022 Equal Cross |

| Hastelloy C22 Equal Tee | Hastelloy UNS N06022 Stub End |

| Nickel C22 Concentric Reducer | C22 Hastelloy 5D Elbow |

Get a Quote of ASME B16.9 Pipe Elbow. Purchase Hastelloy UNS N06022 Eccentric Reducer at reasonable price, Largest distributor of small-quantity DIN 2.4602 Reducing Tee. Fast Delivery and cost-effective rates for C22 Hastelloy Alloy Reducer, Accept all small/ Large Orders of Alloy C22 Equal Tee

Exclusive Ready Stock of Hastelloy UNS N06022 Fittings

UNS N06022 45Deg. Pipe Elbow

Hastelloy C22 Buttweld Pipe Cap

ASME SB366 Alloy C276 Long Radius Elbow

DIN 2.4602 Fabricated Tee

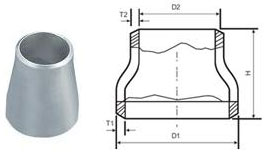

| Nominal Diameter | Outside Diameter | End to End | ||

| D1*D2 | ||||

| DN | NPS | Series A | Series B | H |

| 20*15 | 3/4*1/2 | 26.9*21.3 | 25*18 | 38 |

| 20*10 | 3/4*3/8 | 26.9*17.3 | 25*14 | 38 |

| 25*20 | 1*3/4 | 33.7*26.9 | 32*25 | 51 |

| 25*15 | 1*1/2 | 33.7*21.3 | 32*18 | 51 |

| 32*25 | 1.1/4*1 | 42.4*33.7 | 38*32 | 51 |

| 32*20 | 1.1/4*3/4 | 42.4*26.9 | 38*25 | 51 |

| 32*15 | 1.1/4*1/2 | 42.4*21.3 | 38*18 | 51 |

| 40*32 | 1.1/2*1.1/4 | 48.3*42.4 | 45*38 | 64 |

| 40*25 | 1.1/2*1 | 48.3*33.7 | 45*32 | 64 |

| 40*20 | 1.1/2*3/4 | 48.3*26.9 | 45*25 | 64 |

| 40*15 | 1.1/2*1/2 | 48.3*21.3 | 45*18 | 64 |

| 50*40 | 2*1.1/2 | 60.3*48.3 | 57*45 | 76 |

| 50*32 | 2*1.1/4 | 60.3*42.4 | 57*38 | 76 |

| 50*25 | 2*1 | 60.3*33.7 | 57*32 | 76 |

| 50*20 | 2*3/4 | 60.3*26.9 | 57*25 | 76 |

| 65*50 | 2.1/2*2 | 73.0*60.3 | 76*57 | 89 |

| 65*40 | 2.1/2*1.1/2 | 73.0*48.3 | 76*45 | 89 |

| 65*32 | 2.1/2*1.1/4 | 73.0*42.4 | 76*38 | 89 |

| 65*25 | 2.1/2*1 | 73.0*33.7 | 76*32 | 89 |

| 80*65 | 3*2.1/2 | 88.9*73.0 | 89*76 | 89 |

| 80*50 | 3*2 | 88.9*60.3 | 89*57 | 89 |

| 80*40 | 3*1.1/2 | 88.9*48.3 | 89*45 | 89 |

| 80*32 | 3*1.1/4 | 88.9*42.4 | 89*38 | 89 |

| 90*80 | 3.1/2*3 | 101.6*88.9 | – | 102 |

| 90*65 | 3.1/2*2.1/2 | 101.6*73.0 | – | 102 |

| 90*50 | 3.1/2*2 | 101.6*60.3 | – | 102 |

| 90*40 | 3.1/2*1.1/2 | 101.6*48.3 | – | 102 |

| 90*32 | 3.1/2*1.1/4 | 101.6*42.4 | – | 102 |

| 100*90 | 4*3.1/2 | 114.3*101.6 | – | 102 |

| 100*80 | 4*3 | 114.3*88.9 | 108*89 | 102 |

| 100*65 | 4*2.1/2 | 114.3*73.0 | 108*76 | 102 |

| 100*50 | 4*2 | 114.3*60.3 | 108*57 | 102 |

| 100*40 | 4*1.1/2 | 114.3*48.3 | 108*45 | 102 |

| 125*100 | 5*4 | 141.3*114.3 | 133*108 | 127 |

| 125*90 | 5*3.1/2 | 141.3*101.6 | – | 127 |

| 125*80 | 5*3 | 141.3*88.9 | 133*89 | 127 |

| 125*65 | 5*2.1/2 | 141.3*73.0 | 133*76 | 127 |

| 125*50 | 5*2 | 141.3*60.3 | 133*57 | 127 |

| 150*125 | 6*5 | 168.3*141.3 | 159*133 | 140 |

| 150*100 | 6*5 | 168.3*114.3 | 159*108 | 140 |

| 150*90 | 6*3.1/2 | 168.3*101.6 | – | 140 |

| 150*80 | 6*3 | 168.3*88.9 | 159*89 | 140 |

| 150*65 | 6*2.1/2 | 168.3*73.0 | 159*76 | 140 |

| 200*150 | 8*6 | 219.1*168.3 | 219*159 | 152 |

| 200*125 | 8*5 | 219.1*141.3 | 219*133 | 152 |

| 200*100 | 8*4 | 219.1*114.3 | 219*108 | 152 |

| 200*90 | 8*3.1/2 | 219.1*101.6 | – | 152 |

| 250*200 | 10*8 | 273.0*219.1 | 273*219 | 178 |

| 250*150 | 10*6 | 273.0*168.3 | 273*159 | 178 |

| 250*125 | 10*5 | 273.0*141.3 | 273*133 | 178 |

| 250*100 | 10*4 | 273.0*114.3 | 273*108 | 178 |

| 300*250 | 12*10 | 323.9*273.1 | 325*273 | 203 |

| 300*200 | 12*8 | 323.9*219.1 | 325*219 | 203 |

| 300*150 | 12*6 | 323.9*168.3 | 325*159 | 203 |

| 300*125 | 12*5 | 323.9*141.3 | 325*133 | 203 |

| 350*300 | 14*12 | 355.6*323.9 | 377*325 | 330 |

| 350*250 | 14*10 | 355.6*273.0 | 377*273 | 330 |

| 350*200 | 14*8 | 355.6*219.1 | 377*219 | 330 |

| 350*150 | 14*6 | 355.6*168.3 | 377*159 | 330 |

| 400*350 | 16*14 | 406.4*355.6 | 426*377 | 356 |

| 400*300 | 16*12 | 406.4*323.9 | 426*325 | 356 |

| 400*250 | 16*10 | 406.4*273.0 | 426*273 | 356 |

| 400*200 | 16*8 | 406.4*219.1 | 426*219 | 356 |

| 450*400 | 18*16 | 457*406.4 | 478*426 | 381 |

| 450*350 | 18*14 | 457*355.6 | 478*377 | 381 |

| 450*300 | 18*12 | 457*323.9 | 478*325 | 381 |

| 450*250 | 18*10 | 457*273.0 | 478*273 | 381 |

| 500*450 | 20*18 | 508*457 | 529*478 | 508 |

| 500*400 | 20*16 | 508*406.4 | 529*426 | 508 |

| 500*350 | 20*14 | 508*355.6 | 529*377 | 508 |

| 500*300 | 20*12 | 508*323.9 | 529*325 | 508 |

| 550*500 | 22*20 | 559*508 | – | 508 |

| 550*450 | 22*18 | 559*457 | – | 508 |

| 550*400 | 22*16 | 559*406.4 | – | 508 |

| 550*350 | 22*14 | 559*355.6 | – | 508 |

| 600*550 | 24*22 | 610*559 | – | 508 |

| 600*500 | 24*20 | 610*508 | 630*529 | 508 |

| 600*450 | 24*18 | 610*457 | 630*478 | 508 |

| 600*400 | 24*22 | 610*406.4 | 630*426 | 508 |

| 650*600 | 26*24 | 660*610 | – | 610 |

| 650*550 | 26*22 | 660*559 | – | 610 |

| 650*500 | 26*20 | 660*508 | – | 610 |

| 650*450 | 26*18 | 660*457 | – | 610 |

| 700*650 | 28*26 | 711*660 | – | 610 |

| 700*600 | 28*24 | 711*610 | 720*630 | 610 |

| 700*550 | 28*22 | 711*559 | – | 610 |

| 700*500 | 28*20 | 711*508 | 720*530 | 610 |

| 750*700 | 30*28 | 762*711 | – | 610 |

| 750*650 | 30*26 | 762*660 | – | 610 |

| 750*600 | 30*24 | 762*610 | – | 610 |

| 750*550 | 30*22 | 762*559 | – | 610 |

| 800*750 | 32*30 | 813*762 | – | 610 |

| 800*700 | 32*28 | 813*711 | 820*720 | 610 |

| 800*650 | 32*26 | 813*660 | – | 610 |

| 800*600 | 32*24 | 813*610 | 820*630 | 610 |

| 850*800 | 34*32 | 864*813 | – | 610 |

| 850*750 | 34*30 | 864*762 | – | 610 |

| 850*700 | 34*28 | 864*711 | – | 610 |

| 850*650 | 34*26 | 864*660 | – | 610 |

| 900*850 | 36*34 | 914*864 | – | 610 |

| 900*800 | 36*32 | 914*813 | 920*820 | 610 |

| 900*750 | 36*30 | 914*762 | – | 610 |

| 900*700 | 36*28 | 914*711 | 920*720 | 610 |

| 950*900 | 38*36 | 965*914 | – | 610 |

| 950*850 | 38*34 | 965*864 | – | 610 |

| 950*800 | 38*32 | 965*813 | – | 610 |

| 950*750 | 38*30 | 965*762 | – | 610 |

| 1000*950 | 40*38 | 1016*965 | – | 610 |

| 1000*900 | 40*36 | 1016*914 | 1020*920 | 610 |

| 1000*850 | 40*34 | 1016*864 | – | 610 |

| 1000*800 | 40*32 | 1016*813 | 1020*820 | 610 |

| 1050*1000 | 42*40 | 1067*1016 | – | 610 |

| 1050*950 | 42*38 | 1067*965 | – | 610 |

| 1050*900 | 42*36 | 1067*914 | – | 610 |

| 1050*850 | 42*34 | 1067*864 | – | 610 |

| 1100*1050 | 44*42 | 1118*1067 | – | 610 |

| 1100*1000 | 44*40 | 1118*1016 | 1120*1020 | 610 |

| 1100*950 | 44*38 | 1118*965 | – | 610 |

| 1100*900 | 44*36 | 1118*914 | 1220*920 | 610 |

| 1150*1100 | 46*44 | 1168*1118 | – | 711 |

| 1150*1050 | 46*42 | 1168*1067 | – | 711 |

| 1150*1000 | 46*40 | 1168*1016 | – | 711 |

| 1150*950 | 46*38 | 1168*965 | – | 711 |

| 1200*1150 | 48*46 | 1220*1168 | – | 711 |

| 1200*1100 | 48*44 | 1220*1118 | 1220*1120 | 711 |

| 1200*1050 | 48*42 | 1220*1067 | – | 711 |

| 1200*1000 | 48*40 | 1220*1016 | 1220*1020 | 711 |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Hastelloy C22 | 8.69 g/cm3 | 1399 °C (2550 °F) | Psi – 1,00,000 , MPa – 690 | Psi – 45000 , MPa – 310 | 45 % |

| Grade | C | Mn | Si | S | Co | Ni | Cr | Fe | Mo | P |

| C22 | 0.010 max | 0.50 max | 0.08 max | 0.02 max | 2.50 max | 50.015 min* | 20.00 – 22.50 | 2.00 – 6.00 | 12.50 – 14.50 | 0.02 max |

| STANDARD | WERKSTOFF NR. | UNS | JIS | GOST | EN | OR |

| Hastelloy C22 | 2.4602 | N06022 | NW 6022 | – | NiCr21Mo14W | – |

Largest trader of small-quantity Hastelloy C22 Lateral Tee, Get a Quote from us for Hastelloy C22 Pipe Elbow, Buy Certified & Tested Hastelloy UNS N06022 Seamless Pipe Fittings, Own stockyard of ASTM B366 Alloy C22 Long Stub End. Hastelloy Alloy C22 Pipe bend, Hastelloy Alloy C22 Buttweld Fitting.

| UNS: |

N06022 |

|

Specifications: |

ASTM B366 |

| Nominal Pipe Size | All Fittings | All Fittings | All Fittings | Elbows/ Tees | 180° Return Bends | 180° Return Bends | 180 Deg Return Bends | Reducers | Caps |

|---|---|---|---|---|---|---|---|---|---|

| NPS | O.D. at Bevel (1), (2) | I.D. at End (1), (3), (4) |

Wall Thickness (3) | Centre-to-End Dimension A,B,C,M | Centre-to-Centre O | Back-to-Face K | Alignment of Ends U | Overall Length H | Overall Length E |

| ½ to 2½ | 0.06 -0.03 |

0.03 | Not less than 87.5% of nominal thickness | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.12 |

| 3 to 3 ½ | 0.06 | 0.06 | Not less than 87.5% of nominal thickness | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.12 |

| 4 | 0.06 | 0.06 | Not less than 87.5% of nominal thickness | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.12 |

| 5 to 8 | 0.09 -0.06 |

0.06 | Not less than 87.5% of nominal thickness | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.25 |

| 10 to 18 | 0.16 -0.12 |

0.12 | Not less than 87.5% of nominal thickness | 0.09 | 0.38 | 0.25 | 0.06 | 0.09 | 0.25 |

| 20 to 24 | 0.25 -0.19 |

0.19 | Not less than 87.5% of nominal thickness | 0.09 | 0.38 | 0.25 | 0.06 | 0.09 | 0.25 |

| 26 to 30 | 0.25 -0.19 |

0.19 | Not less than 87.5% of nominal thickness | 0.12 | … | … | … | 0.19 | 0.38 |

| 32 to 48 | 0.25 -0.19 |

0.19 | Not less than 87.5% of nominal thickness | 0.19 | … | … | … | 0.19 | 0.38 |