Hastelloy B2 Pipe Fittings

- Home

- Hastelloy B2 Pipe Fittings

Check ASTM B366 Alloy B2 Elbow Price List, Alloy B3/ B2 Elbow Manufacturer

Both Hastelloy B2, as well as Hastelloy B3 Fittings, offer good resistance to non-oxidizing acids, such as hydrochloric acid and sulfuric acid. We do not recommend using the Alloy B3/ B2 Elbow in oxidizing media or exposing these fittings to either ferric or cupric salts. This is because both these alloys i.e. B3 and Hastelloy B2 Fittings are susceptible to corrosion failure. The only advantages of using a Hastelloy B3 Elbow over alloy grade B2 fittings is that B3 generally offers much better thermal stability as well as improved fabrication characteristics.

Hastelloy B2 Pipe Fittings

Alloy B3/ B2 Elbow

Hastelloy DIN 2.4600 Buttweld Tee

Get Best Price & Fast Delivery For Hastelloy B2 Fittings, Biggest Hastelloy B3 Elbow Manufacturers, 8 Inch Hastelloy B2 Reducer Suppliers.

Apart from having excellent resistance to local attack such as pitting and SCC or stress corrosion cracking, the Hastelloy B2 Pipe Fittings also has the ability to resist knife-line and heat-affected zone attack. Moreover, the Hastelloy B2 Stub End provides resistance to pure sulfuric acid while exhibiting resilience to a number of non-oxidizing acids.

Table of Content

- What is Alloy B3 Fittings?

- Price List of Alloy B3 Pipe Fittings

- Material Specification of Hastelloy B2 Pipe Fittings

- Various Types of Hastelloy B2 Fittings

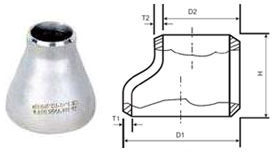

- ASTM B366 UNS N10665 Eccentric Reducer Dimensions & Weight

- Hastelloy UNS N010675 Pipe Fittings Mechanical Strength

- Chemical Compatibility of Hastelloy DIN 2.4617 Fittings

- Hastelloy Alloy B3 Fittings Equivalent grades

- Specification Standard of Nickel B2 Fittings

- Available Forms of Hastelloy B2 Fittings

An important point to note is since both alloy grades i.e. B2 and B3 Hastelloy DIN 2.4600 Buttweld Tee have lower carbon contents, they can be used in an as-welded condition because these fittings have the ability to not promote the formation of grain-boundary carbide precipitates that takes place during welding in the weld heat-affected zone. A characteristically good feature of the Hastelloy B2 Reducer is its controlled chemistry with fewer contents of both elements, chromium and iron which in turn are able to retard ordered β phase Ni4Mo.

| Specification | ASTM B366 / ASME SB366 |

| Thickness | Sch 5s, Sch 10s, Sch 40s, Sch 80s, Sch 160s, Sch XXS |

| Bending Radius | R= 2D, 6D, 1D, 5D, 8D, 3D, 10D or Custom |

| Size | Seamless 1/2" - 10", Welded 1/2" - 48" |

| Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43 |

| Type | Seamless / Welded / Fabricated |

| Pipe Fittings Forms | Long Radius (LR) Elbow, Short Radius (SR) Elbow, 2D Elbow, 3D Elbow, 5D Elbow, 10D Elbow, Equal Cross, Unequal Crosses, Reducing Nipple, Butt Tee Fittings, Bend, Swedge Nipple, Pipe Nipple, Reducers, Caps, Stub End, Pipe / Piggable Bend, Elbow, 45 and 90° elbows, 180° bends, lap-joint stub ends |

We are Delivering Hastelloy B2 Stub End everywhere Worldwide, We stock a range of Alloy B3 Fittings in different sizes, Buy online Alloy B2 Elbow at factory price, Ask for free sample of UNS N10665 Reducing Stub End

| Alloy B3 Fittings | Hastelloy B2 Pipe Fitting |

| B2 Hastelloy 90 Degree Elbow | Hastelloy UNS N010675 End Cap |

| Nickel B2 45 Degree Elbow | Hastelloy DIN 2.4617 Buttweld Fitting |

| Nickel Alloy B2 1D Elbow | Hastelloy Alloy B3 Short Stub End |

| Hastelloy DIN 2.4617 Stub End | Alloy B3 Pipe Cap |

| ASTM B366 UNS N10665 3D Elbow | Hastelloy 2.4600 End Cap |

| Hastelloy B2 5D Elbow | Hastelloy 2.4600 Reducer |

| Alloy B3 Buttweld Fittings | Hastelloy UNS N010675 Pipe Bend |

| Nickel B2 Pipe Fittings | Nickel Alloy B2 Long Stub End |

| Hastelloy DIN 2.4617 Eccentric Reducer | Nickel Alloy B2 Long Radius Elbow |

| Hastelloy 2.4600 Concentric Reducer | B2 Hastelloy Short Radius Elbow |

| Nickel B2 Equal Cross | Alloy B3 Pipe Cap |

| Hastelloy UNS N010675 Lateral Tee | ASTM B366 UNS N10665 Cross Tee |

| Hastelloy Alloy B3 Reducing Cross | Hastelloy DIN 2.4617 Equal Cross |

| Hastelloy B2 Equal Tee | Hastelloy 2.4600 Stub End |

| Hastelloy UNS N010675 Concentric Reducer | Nickel B2 5D Elbow |

ASTM B366 Alloy B2 Elbow are available in different sizes & schedules. Buy directly from B2 Hastelloy Alloy Reducer stockist, Top-notch supplier of ASTM B366 Hastelloy B2 Tee. Check Availability of Hastelloy B2 Pipe Elbow, Ask for free sample of Hastelloy UNS N10665 Seamless Pipe Fittings.

Exclusive Ready Stock of Hastelloy 2.4600 Fittings

Hastelloy DIN 2.4617 Eccentric Reducer

Hastelloy UNS N10665 Equal Tee

Hastelloy Alloy DIN 2.4617 Short Stub End

ASTM B366 B2 Hastelloy End Cap

| Nominal Diameter | Outside Diameter | End to End | ||

| D1*D2 | ||||

| DN | NPS | Series A | Series B | H |

| 20*15 | 3/4*1/2 | 26.9*21.3 | 25*18 | 38 |

| 20*10 | 3/4*3/8 | 26.9*17.3 | 25*14 | 38 |

| 25*20 | 1*3/4 | 33.7*26.9 | 32*25 | 51 |

| 25*15 | 1*1/2 | 33.7*21.3 | 32*18 | 51 |

| 32*25 | 1.1/4*1 | 42.4*33.7 | 38*32 | 51 |

| 32*20 | 1.1/4*3/4 | 42.4*26.9 | 38*25 | 51 |

| 32*15 | 1.1/4*1/2 | 42.4*21.3 | 38*18 | 51 |

| 40*32 | 1.1/2*1.1/4 | 48.3*42.4 | 45*38 | 64 |

| 40*25 | 1.1/2*1 | 48.3*33.7 | 45*32 | 64 |

| 40*20 | 1.1/2*3/4 | 48.3*26.9 | 45*25 | 64 |

| 40*15 | 1.1/2*1/2 | 48.3*21.3 | 45*18 | 64 |

| 50*40 | 2*1.1/2 | 60.3*48.3 | 57*45 | 76 |

| 50*32 | 2*1.1/4 | 60.3*42.4 | 57*38 | 76 |

| 50*25 | 2*1 | 60.3*33.7 | 57*32 | 76 |

| 50*20 | 2*3/4 | 60.3*26.9 | 57*25 | 76 |

| 65*50 | 2.1/2*2 | 73.0*60.3 | 76*57 | 89 |

| 65*40 | 2.1/2*1.1/2 | 73.0*48.3 | 76*45 | 89 |

| 65*32 | 2.1/2*1.1/4 | 73.0*42.4 | 76*38 | 89 |

| 65*25 | 2.1/2*1 | 73.0*33.7 | 76*32 | 89 |

| 80*65 | 3*2.1/2 | 88.9*73.0 | 89*76 | 89 |

| 80*50 | 3*2 | 88.9*60.3 | 89*57 | 89 |

| 80*40 | 3*1.1/2 | 88.9*48.3 | 89*45 | 89 |

| 80*32 | 3*1.1/4 | 88.9*42.4 | 89*38 | 89 |

| 90*80 | 3.1/2*3 | 101.6*88.9 | – | 102 |

| 90*65 | 3.1/2*2.1/2 | 101.6*73.0 | – | 102 |

| 90*50 | 3.1/2*2 | 101.6*60.3 | – | 102 |

| 90*40 | 3.1/2*1.1/2 | 101.6*48.3 | – | 102 |

| 90*32 | 3.1/2*1.1/4 | 101.6*42.4 | – | 102 |

| 100*90 | 4*3.1/2 | 114.3*101.6 | – | 102 |

| 100*80 | 4*3 | 114.3*88.9 | 108*89 | 102 |

| 100*65 | 4*2.1/2 | 114.3*73.0 | 108*76 | 102 |

| 100*50 | 4*2 | 114.3*60.3 | 108*57 | 102 |

| 100*40 | 4*1.1/2 | 114.3*48.3 | 108*45 | 102 |

| 125*100 | 5*4 | 141.3*114.3 | 133*108 | 127 |

| 125*90 | 5*3.1/2 | 141.3*101.6 | – | 127 |

| 125*80 | 5*3 | 141.3*88.9 | 133*89 | 127 |

| 125*65 | 5*2.1/2 | 141.3*73.0 | 133*76 | 127 |

| 125*50 | 5*2 | 141.3*60.3 | 133*57 | 127 |

| 150*125 | 6*5 | 168.3*141.3 | 159*133 | 140 |

| 150*100 | 6*5 | 168.3*114.3 | 159*108 | 140 |

| 150*90 | 6*3.1/2 | 168.3*101.6 | – | 140 |

| 150*80 | 6*3 | 168.3*88.9 | 159*89 | 140 |

| 150*65 | 6*2.1/2 | 168.3*73.0 | 159*76 | 140 |

| 200*150 | 8*6 | 219.1*168.3 | 219*159 | 152 |

| 200*125 | 8*5 | 219.1*141.3 | 219*133 | 152 |

| 200*100 | 8*4 | 219.1*114.3 | 219*108 | 152 |

| 200*90 | 8*3.1/2 | 219.1*101.6 | – | 152 |

| 250*200 | 10*8 | 273.0*219.1 | 273*219 | 178 |

| 250*150 | 10*6 | 273.0*168.3 | 273*159 | 178 |

| 250*125 | 10*5 | 273.0*141.3 | 273*133 | 178 |

| 250*100 | 10*4 | 273.0*114.3 | 273*108 | 178 |

| 300*250 | 12*10 | 323.9*273.1 | 325*273 | 203 |

| 300*200 | 12*8 | 323.9*219.1 | 325*219 | 203 |

| 300*150 | 12*6 | 323.9*168.3 | 325*159 | 203 |

| 300*125 | 12*5 | 323.9*141.3 | 325*133 | 203 |

| 350*300 | 14*12 | 355.6*323.9 | 377*325 | 330 |

| 350*250 | 14*10 | 355.6*273.0 | 377*273 | 330 |

| 350*200 | 14*8 | 355.6*219.1 | 377*219 | 330 |

| 350*150 | 14*6 | 355.6*168.3 | 377*159 | 330 |

| 400*350 | 16*14 | 406.4*355.6 | 426*377 | 356 |

| 400*300 | 16*12 | 406.4*323.9 | 426*325 | 356 |

| 400*250 | 16*10 | 406.4*273.0 | 426*273 | 356 |

| 400*200 | 16*8 | 406.4*219.1 | 426*219 | 356 |

| 450*400 | 18*16 | 457*406.4 | 478*426 | 381 |

| 450*350 | 18*14 | 457*355.6 | 478*377 | 381 |

| 450*300 | 18*12 | 457*323.9 | 478*325 | 381 |

| 450*250 | 18*10 | 457*273.0 | 478*273 | 381 |

| 500*450 | 20*18 | 508*457 | 529*478 | 508 |

| 500*400 | 20*16 | 508*406.4 | 529*426 | 508 |

| 500*350 | 20*14 | 508*355.6 | 529*377 | 508 |

| 500*300 | 20*12 | 508*323.9 | 529*325 | 508 |

| 550*500 | 22*20 | 559*508 | – | 508 |

| 550*450 | 22*18 | 559*457 | – | 508 |

| 550*400 | 22*16 | 559*406.4 | – | 508 |

| 550*350 | 22*14 | 559*355.6 | – | 508 |

| 600*550 | 24*22 | 610*559 | – | 508 |

| 600*500 | 24*20 | 610*508 | 630*529 | 508 |

| 600*450 | 24*18 | 610*457 | 630*478 | 508 |

| 600*400 | 24*22 | 610*406.4 | 630*426 | 508 |

| 650*600 | 26*24 | 660*610 | – | 610 |

| 650*550 | 26*22 | 660*559 | – | 610 |

| 650*500 | 26*20 | 660*508 | – | 610 |

| 650*450 | 26*18 | 660*457 | – | 610 |

| 700*650 | 28*26 | 711*660 | – | 610 |

| 700*600 | 28*24 | 711*610 | 720*630 | 610 |

| 700*550 | 28*22 | 711*559 | – | 610 |

| 700*500 | 28*20 | 711*508 | 720*530 | 610 |

| 750*700 | 30*28 | 762*711 | – | 610 |

| 750*650 | 30*26 | 762*660 | – | 610 |

| 750*600 | 30*24 | 762*610 | – | 610 |

| 750*550 | 30*22 | 762*559 | – | 610 |

| 800*750 | 32*30 | 813*762 | – | 610 |

| 800*700 | 32*28 | 813*711 | 820*720 | 610 |

| 800*650 | 32*26 | 813*660 | – | 610 |

| 800*600 | 32*24 | 813*610 | 820*630 | 610 |

| 850*800 | 34*32 | 864*813 | – | 610 |

| 850*750 | 34*30 | 864*762 | – | 610 |

| 850*700 | 34*28 | 864*711 | – | 610 |

| 850*650 | 34*26 | 864*660 | – | 610 |

| 900*850 | 36*34 | 914*864 | – | 610 |

| 900*800 | 36*32 | 914*813 | 920*820 | 610 |

| 900*750 | 36*30 | 914*762 | – | 610 |

| 900*700 | 36*28 | 914*711 | 920*720 | 610 |

| 950*900 | 38*36 | 965*914 | – | 610 |

| 950*850 | 38*34 | 965*864 | – | 610 |

| 950*800 | 38*32 | 965*813 | – | 610 |

| 950*750 | 38*30 | 965*762 | – | 610 |

| 1000*950 | 40*38 | 1016*965 | – | 610 |

| 1000*900 | 40*36 | 1016*914 | 1020*920 | 610 |

| 1000*850 | 40*34 | 1016*864 | – | 610 |

| 1000*800 | 40*32 | 1016*813 | 1020*820 | 610 |

| 1050*1000 | 42*40 | 1067*1016 | – | 610 |

| 1050*950 | 42*38 | 1067*965 | – | 610 |

| 1050*900 | 42*36 | 1067*914 | – | 610 |

| 1050*850 | 42*34 | 1067*864 | – | 610 |

| 1100*1050 | 44*42 | 1118*1067 | – | 610 |

| 1100*1000 | 44*40 | 1118*1016 | 1120*1020 | 610 |

| 1100*950 | 44*38 | 1118*965 | – | 610 |

| 1100*900 | 44*36 | 1118*914 | 1220*920 | 610 |

| 1150*1100 | 46*44 | 1168*1118 | – | 711 |

| 1150*1050 | 46*42 | 1168*1067 | – | 711 |

| 1150*1000 | 46*40 | 1168*1016 | – | 711 |

| 1150*950 | 46*38 | 1168*965 | – | 711 |

| 1200*1150 | 48*46 | 1220*1168 | – | 711 |

| 1200*1100 | 48*44 | 1220*1118 | 1220*1120 | 711 |

| 1200*1050 | 48*42 | 1220*1067 | – | 711 |

| 1200*1000 | 48*40 | 1220*1016 | 1220*1020 | 711 |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Hastelloy B2 | 8.89 g/cm3 | 1370 °C (2500 °F) | Psi – 1,15,000 , MPa – 790 | Psi – 52,000 , MPa – 355 | 40 % |

| Grade | C | Mn | Si | S | Co | Ni | Cr | Fe | Mo | P |

| B2 | 0.010 max | 1.00 max | 0.08 max | 0.03 max | 2.50 max | 50.99 min* | 14.50 – 16.50 | 4.00 – 7.00 | 15.00 – 17.00 | 0.04 max |

| STANDARD | WERKSTOFF NR. | UNS | JIS | GOST | EN | OR |

| Hastelloy B2 | 2.4617 | N10665 | NW 0276 | ХН65МВУ | NiMo16Cr15W | ??760 |

Specialise in distributing B2 Hastelloy End Cap, Largest independent stockholder Hastelloy DIN 2.4617 Cross. Purchase Alloy B3 Equal Tee at factory price, High Pressure Alloy B2 Short Radius Elbow Dealers. Order custom sizes online for Hastelloy B3 Lateral Tee, Hastelloy Alloy B3 Pipe bend.

| UNS: |

N10665 |

|

Specifications: |

ASME SB-366 |

| 90 Degree Long Radius Elbow | 90 Degree Short Radius Elbow | 45 Degree LR Elbow | Reducing Tee | Concentric Reducer | 180 Degree Long Radius Bend |

| 180 Degree LR Bend | Buttweld Cross | Swage Nipple | Piiggable Bends | Stub Ends as per MSS-SP 43 | 45 Degree Long Radius Elbow |

| 45 Degree Short Radius Elbow | 45 Degree SR Elbow | Equal Tee | Eccentric Reducer | 180 Short Radius Bend | 180 SR Bend |

| Unequal Cross | Concentric Swage Nipple | 3D Bends | Long Stub Ends | 3D Bends | 5D Bends |

| Induction Bends | Miter Bends | U Bends | |||