Nickel 201 Pipe Fittings

- Home

- Nickel 201 Pipe Fittings

View Alloy 201 Reducer Dimensions, ASTM B366 UNS N02201 Reducing Elbow Manufacturer

Nickel 201 Pipe Fittings are known to illustrate good resistance to corrosion to a variety of acids as well as to alkalis. These fittings are found to be useful under conditions that contain reductive agents. Just like Alloy grade 200, the Nickel 201 Pipe Cap demonstrates remarkable resistance to caustic alkalis, especially in the molten condition. Its resistance to alkali is what makes this alloy beneficial if used during the manufacturing of viscose rayon. This property in particular also finds use in programs wherein the Nickel 201 Fittings is to be used in the manufacture as well as the processing of sodium hydroxide which in turn is considered to be an exceptionally caustic base.

Nickel 201 Pipe Fittings

Alloy 201 Reducer

UNS N02201 Reducing Elbow

Check Price list of Nickel 201 Fittings, High Pressure Nickel Alloy 201 Fittings Supplier, Purchase Nickel 201 Elbow at factory price.

Not only the properties but the very popular and versatile ASTM B366 UNS N02201 Reducing Elbow is also specifically immune to sodium hydroxide even at a temperature above 300 °C. Nickel alloyed wrought welding fittings covered under the ASTM B366 include threaded fittings as well. These Nickel Alloy 201 Fittings are designed to be used in pressure piping systems. The term welding, in the specification ASTM B366 applies to butt welding or socket welding parts.

Table of Content

- What is Din 2.4068 Fittings?

- Price List of Din 2.4068 Pipe Fittings

- Spec Chart of Nickel 201 Pipe Fittings

- Most Common types of Nickel 201 Fittings

- Dimensions & Weight Chart UNS N02201 Stub End

- Mechanical Characteristics of Alloy 201 Pipe Fittings

- Chemical Equation of ASTM B366 201 Nickel Buttweld Fittings

- Alloy 201 Nickel Fittings Equivalent

- international Trade Name of Nickel 201 UNS N02201 Fittings

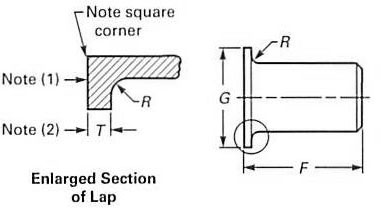

These welded parts include fittings such as various kinds of bends and elbows along with caps, reducers, tees, lap-joint, and stub ends. Alloy 201 Reducer is a fitting that is ideally used when the size of a pipe is to be changed, in this case, reduced from a larger bore to a smaller bore. Used as a substitute for welded flanges, the Nickel 201 Stub End is applied where rotation of a backup flange is required.

| UNS N02201 Pipe Fittings size | Nickel 201 Seamless Butt Weld Fittings: 1/2" - 10" Din 2.4068 Welded Butt Weld Fittings: 1/2" - 48" |

|---|---|

| Nickel 201 UNS N02201 Pipe Fittings Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 |

| 201 Nickel Fittings Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| Nickel 201 Pipe fittings Types |

|

| Nickel 201 FittingsType | DN15-DN1200 |

| ASTM B366 201 Nickel Buttweld Fitting Connection | Welding |

| Bending Radius | R= 2D, 6D, 1D, 5D, 8D, 3D, 10D or Custom Nickel Alloy 201 Pipe Fitting |

| Size Range | ½" NB to 24" NB in Sch 10s, 40s, 80s, 160s, XXS. (DN6~DN100) Alloy 201 Buttweld Fitting |

| ASTM B366 UNS N02201 Elbows | Angle : 22.5 deg, 30deg, 45 deg, 90 deg, 180 deg, 1.0D, 1.5D, 2.0D, 2.5D, 3D, 4D, 5D, 6D, 7D-40D . Standard: ASME B16.9, ASME B16.28, ASME B16.25, MSS SP-75 DIN2605 JISB2311 JISB2312 JISB2313, BS, GB, ISO |

| Nickel 201 Fittings Manufacturing process | Push, Press, Forge, Cast, etc. |

| Nickel 201 Buttweld Pipe Fittings Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Nickel 201 UNS N02201 Pipe Fittings Origin & Mills | Japanese, Indian, USA, Korean, European, Ukraine, Russian |

| Key markets and industries for ASTM B366 UNS N02201 Pipe Fittings |

|

| Specialized manufacturer of | Din 2.4068 90º Elbows, 45º Elbows, Tees, Crosses, Reducers, Pipe Cap, Stub End, Pipe Bend |

| Application & uses of Industrial Alloy 201 Fittings |

|

| We provide Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

Best Price & Fast Delivery for Nickel 201 Tee, One Stop Shop For Nickel 201 Reducer, Held wide stock of Nickel 201 Stub End, Largest independent stockholder Nickel 201 Pipe Cap

| Din 2.4068 Fittings | Nickel 201 Pipe Fitting |

| Nickel Alloy 201 90 Degree Elbow | Alloy 201 End Cap |

| Nickel 201 UNS N02201 45 Degree Elbow | ASTM B366 201 Nickel Buttweld Fitting |

| 201 Nickel 1D Elbow | Alloy 201 Nickel Short Stub End |

| ASTM B366 201 Nickel Stub End | Din 2.4068 Pipe Cap |

| UNS N02201 3D Elbow | ASTM B366 UNS N02201 End Cap |

| Nickel 201 5D Elbow | ASTM B366 UNS N02201 Reducer |

| Din 2.4068 Buttweld Fittings | Alloy 201 Pipe Bend |

| Nickel 201 UNS N02201 Pipe Fittings | 201 Nickel Long Stub End |

| ASTM B366 201 Nickel Eccentric Reducer | 201 Nickel Long Radius Elbow |

| ASTM B366 UNS N02201 Concentric Reducer | Nickel Alloy 201 Short Radius Elbow |

| Nickel 201 UNS N02201 Equal Cross | Din 2.4068 Pipe Cap |

| Alloy 201 Lateral Tee | UNS N02201 Cross Tee |

| Alloy 201 Nickel Reducing Cross | ASTM B366 201 Nickel Equal Cross |

| Nickel 201 Equal Tee | ASTM B366 UNS N02201 Stub End |

| Alloy 201 Concentric Reducer | Nickel 201 UNS N02201 5D Elbow |

Distributing globally Nickel 201 Cross at best prices. DIN 2.4068 Pipe Tee are available in different sizes to fulfill any requirement, One of India’s largest Manufacturer ANSI B16.9 Buttweld Reducer, Suppliers and Stockists of ASME SB366 UNS N02201 Fittings. Schedule 80 201 Nickel Alloy Reducer are ready to dispatch if ordered today.

Purchase ASTM B366 UNS N02201 Fittings at Best Price

ASTM B366 UNS N02201 Concentric Reducer

Nickel 201 UNS N02201 45 Degree Elbow

Nickel 201 Pipe Fittings

Nickel 201 UNS N02201 Equal Cross

| Nominal Pipe Size | Outside diameterof barrel | Length (F) | Radius (R) | Diameter (G) | ||

|---|---|---|---|---|---|---|

| Minimum | Maximum | LongPattern | ShortPattern | |||

| 1/2″ | 20.5 | 22.8 | 76 | 51 | 3 | 35 |

| 3/4″ | 25.9 | 28.1 | 76 | 51 | 3 | 43 |

| 1″ | 32.6 | 35.0 | 102 | 51 | 3 | 51 |

| 1 1/4″ | 41.4 | 43.6 | 102 | 51 | 5 | 64 |

| 1 1/2″ | 47.5 | 49.9 | 102 | 51 | 6 | 74 |

| 2″ | 59.5 | 62.4 | 152 | 64 | 8 | 92 |

| 2 1/2″ | 72.2 | 75.3 | 152 | 64 | 8 | 105 |

| 3″ | 88.1 | 91.3 | 152 | 64 | 10 | 127 |

| 3 1/2″ | 100.8 | 104.0 | 152 | 76 | 10 | 140 |

| 4″ | 113.5 | 116.7 | 152 | 76 | 11 | 157 |

| 5″ | 140.5 | 144.3 | 203 | 76 | 11 | 186 |

| 6″ | 167.5 | 171.3 | 203 | 89 | 13 | 216 |

| 8″ | 218.3 | 222.1 | 203 | 102 | 13 | 270 |

| 10″ | 272.3 | 277.2 | 254 | 127 | 13 | 324 |

| 12″ | 323.1 | 328.0 | 254 | 152 | 13 | 381 |

| 14″ | 354.8 | 359.9 | 305 | 152 | 13 | 413 |

| 16″ | 405.6 | 411.0 | 305 | 152 | 13 | 470 |

| 18″ | 456.0 | 462.0 | 305 | 152 | 13 | 533 |

| 20″ | 507.0 | 514.0 | 305 | 152 | 13 | 584 |

| 22″ | 558.0 | 565.0 | 305 | 152 | 13 | 641 |

| 24″ | 609.0 | 616.0 | 305 | 152 | 13 | 692 |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Nickel 201 | 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 67000 , MPa – 462 | Psi – 21500 , MPa – 148 | 45 % |

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

| Nickel 201 | 0.02 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Nickel 201 | 2.4068 | N02201 | NW 2201 | NA 12 | ??-2 | – | LC-Ni 99 |

Best Price & Fast Delivery for Nickel Alloy 201 Pipe Bend, Own stockyard of 201 Nickel Alloy End Cap, Biggest supplier of small-quantity Nickel Alloy 201 Buttweld Fittings, Largest Manufacturer Alloy 201 Short Radius Elbow. Nickel DIN 2.4068 Cross, Contact us today to buy Nickel 201 Lateral Tee at 10% discounted rate.

| UNS: |

N02201 |

|

Specifications: |

ASME SB-366 |

|

international Specifications: |

BS 3072, BS 3073, BS 3074, BS 3075, BS 3076, NA11 DIN 17740, 17750, 17751, 17752, 17753, 17754 Werkstoff Nr. 2.4060, 2.4066 |