Nickel 200 Flanges

- Home

- Nickel 200 Flanges

View Alloy 200 Slip on Flange Price List, Check ASTM B564 UNS N02200 Weld Neck Flange Dimensions & Sizes

Under situations that contain reductive compounds, the Nickel 200 Flanges proves to be most useful alloy grades. In fact, the Nickel 200 RTJ Flange has the potential to offer accurate resistance to corrosion not only in acids but also alkalis. For this particular reason, the ASTM B564 specified nickel 200 fittings have been used in the manufacture as well as handling or processing of sodium hydroxide. Predominantly these fittings must be limited to being used for applications above a temperature of about 300 degrees C.

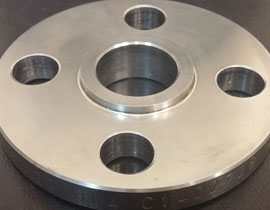

Nickel 200 Flanges

Alloy 200 Slip on Flange

ASTM B564 UNS N02200 Weld Neck Flange

Ready stock of Nickel 200 Slip on Flange at reasonable cost, Get Latest Price List of Nickel 200 Weld Neck Flange, Leading Nickel 200 Lap Joint Flange Supplier.

In fact, the Nickel 200 Lap Joint Flange has incredible resistance to caustic alkalis exclusively in a molten state. despite the fact that the Nickel 200 Weld Neck Flange is a material which indicates excellent resistance in acidic, alkaline and impartial salt compounds, however, when the same alloy has been exposed to an oxidizing salt containing solution, the material might be prone severe attack. Alloy 200 Slip on Flange offers resistance against all dry gases at room temperature.

Table of Content

- What is Nickel 200 Flange?

- Nickel 200 UNS N02200 Flange Price

- Material Specification of Nickel 200 Flanges

- Dimensions Chart of Alloy 200 Class 2500 Flange

- Different Types of 200 Nickel Flange

- Din 2.4066 Flange Standards Material Specification

- Equivalent Material of Alloy 200 Nickel Flange

- Mechanical Behaviour of Nickel Alloy 200 Flange

- Chemical Equation of UNS N02200 Flange

- 350mm (14") ASTM B564 UNS N02200 Flange Weight Chart

The material for ASTM B564 UNS N02200 Weld Neck Flange additionally has the capacity to resist dry chlorine and hydrogen chloride. Consequently, nickel based alloy 200 will be used in temperatures as much as 550°C. Resistance property of the Nickel 200 Slip on Flange to mineral acids varies depending on not only the temperature and concentration but also if the acidic solution has been aerated or not since the alloy exemplifies its corrosion resistance properties in de-aerated acids in a much better manner.

| Grade | Nickel Alloy 200 / UNS N02200 |

| Class / Pressure Rating | 150 Class, 300 Class, 200 Class, 900 Class, 1500 Class, 2500 Class, PN6, PN10, PN16, PN25, PN40, PN64, etc. |

| Standard | ASTM B564, ASME SB564 |

| Dimensions | ANSI / ASME B16.5, B16.47 Series A & B, B.16.48, BS4504, BS10, DIN, EN-1092, MSS SP44 |

| Size | 1/2" - 48" (15NB - 1200NB) |

| Flange Face Type | Flat Face (FF), Raised Face (RF), Ring Type Joint(RTJ) |

| Form | Weld neck Flanges (WNRF), Blind Flanges, Socket weld Flanges, Slip on Flanges (SORF), Threaded Flanges, Lap Joint Flanges, Ring Type Joint Flanges, Spectacle Blind Flanges, Spacer Ring Flanges, Long weld Neck Flanges, Nipo Flange, Nipolet Flanges, Plate Flanges, Flat Flange, Orifice Flanges, Forged Flanges |

Nickel 200 RTJ Flange available in wider range of sizes, One Stop Shop For Nickel 200 Blind Flange, Specialise in Supplying Nickel 200 Spectacle Blind Flange, Stockholder of Nickel UNS N02200 Pipe Flanges

| Nominal Size |

Outside Diameter (OD) |

Min. Thickness (T) |

RF Dia. (R) |

No. of Bolt Holes | Diameter of Holes |

Bolt Circle (BC) |

Dia. Hub Base (HB) |

Dia. Hub Top (HT) |

SO LTH (SL) |

WN LTH (WL) |

* WN Bore ID (WB) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1⁄2 | 5.25 | 1.19 | 1.38 | 4 | 0.88 | 3.50 | 1.69 | 0.84 | 1.56 | 2.88 | * |

| 3⁄4 | 5.50 | 1.25 | 1.69 | 4 | 0.88 | 3.75 | 2.00 | 1.05 | 1.69 | 3.12 | * |

| 1 | 6.25 | 1.38 | 2.00 | 4 | 1.00 | 4.25 | 2.25 | 1.32 | 1.88 | 3.50 | * |

| 11⁄4 | 7.25 | 1.50 | 2.50 | 4 | 1.12 | 5.13 | 2.88 | 1.66 | 2.06 | 3.75 | * |

| 11⁄2 | 8.00 | 1.75 | 2.88 | 4 | 1.25 | 5.75 | 3.12 | 1.90 | 2.38 | 4.38 | * |

| 2 | 9.25 | 2.00 | 3.63 | 8 | 1.12 | 6.75 | 3.75 | 2.38 | 2.75 | 5.00 | * |

| 21⁄2 | 10.50 | 2.25 | 4.13 | 8 | 1.25 | 7.75 | 4.50 | 2.88 | 3.12 | 5.62 | * |

| 3 | 12.00 | 2.62 | 5.00 | 8 | 1.38 | 9.00 | 5.25 | 3.50 | – | 6.62 | * |

| 4 | 14.00 | 3.00 | 6.19 | 8 | 1.63 | 10.75 | 6.50 | 4.50 | – | 7.50 | * |

| 5 | 16.50 | 3.62 | 7.31 | 8 | 1.88 | 12.75 | 8.00 | 5.56 | – | 9.00 | * |

| 6 | 19.00 | 4.25 | 8.50 | 8 | 2.12 | 14.50 | 9.25 | 6.63 | – | 10.75 | * |

| 8 | 21.75 | 5.00 | 10.63 | 12 | 2.12 | 17.25 | 12.00 | 8.63 | – | 12.50 | * |

| 10 | 26.50 | 6.50 | 12.75 | 12 | 2.63 | 21.25 | 14.75 | 10.75 | – | 16.50 | * |

| 12 | 30.00 | 7.25 | 15.00 | 12 | 2.88 | 24.38 | 17.38 | 12.75 | – | 18.25 | * |

| Nickel Alloy 200 Flange | Nickel 200 Blind Flange |

| Din 2.4066 Slip on Flange | ASTM B564 200 Nickel Threaded Flange |

| Nickel Alloy 200 Reducing Flange | Nickel 200 UNS N02200 Socket Weld Flange |

| ASTM B564 200 Nickel Weld Neck Flanges | Nickel 200 Lap Joint Flanges |

| 200 Nickel Long Weld Neck Flanges | Nickel Alloy 200 Spectacle Blind Flanges |

| ASTM B564 200 Nickel Spades & Ring Spacers | Nickel 200 UNS N02200 Nipoflange |

| Nickel 200 5D Weldoflange | UNS N02200 Flange Outlet |

| Nickel Alloy 200 Forged Flanges | ASTM B564 UNS N02200 Plate Flange |

| Nickel Alloy 200 Ring Type Joint Flanges | Nickel 200 UNS N02200 Raised Face Flanges |

| Nickel 200 Tongue and Groove Flanges | ASTM B564 UNS N02200 Male and Female Flange |

| ASTM B564 200 Nickel Reducing Flanges | Nickel Alloy 200 ASME B16.5 Flanges |

| UNS N02200 Flanges | Din 2.4066 BS 10 Flanges |

| Nickel 200 BS 4504 Flanges | Nickel 200 UNS N02200 EN 1092-1 Flanges |

| 200 Nickel SORF Flange | Nickel Alloy 200 BLRF Flange |

| UNS N02200 WNRF Flange | Din 2.4066 RTJ Flange |

| Nickel 200 Series a Lap Joint Ring Flange | Nickel 200 UNS N02200 Class 300 threaded flange |

| Nickel Alloy 200 PN16 blind flange | Alloy 200 Nickel Forged Socket Weld Pipe Flange |

| Nickel 200 Class 300 slip on flange | ASTM B564 200 Nickel Slip On Weld Flange |

| Din 2.4066 Forged steel slip on flanges | Din 2.4066 Race face slip on flange |

| UNS N02200 SWRF Flange | Alloy 200 Nickel Forged blind flange |

| Nickel 200 groove weld neck flange | 200 Nickel Socket Weld Hub Flange |

| UNS N02200 threaded lap joint flange | Alloy 200 Nickel Slip On Integral flange |

| Nickel 200 Forged integral puddle flange | Din 2.4066 table e long weld neck |

| Nickel Alloy 200 Class 150 LBS Flange | ASTM B564 UNS N02200 PN10 Forged Flanges |

| Nickel 200 RTJ Flanges | ASTM B564 200 Nickel PN10 Plate Flanges |

| Nickel Alloy 200 Tongue & Groove Flanges | Nickel 200 Reducing Flanges |

| Din 2.4066 Class 150 reducing threaded flange | Din 2.4066 Class 150 Pipe Flange |

| 200 Nickel Class 150 Flange | Alloy 200 Nickel Pipe Flanges |

| Nickel Alloy 200 BS 10 Flanges | Alloy 200 Class 150 Tongue & Groove Flanges |

| Din 2.4066 BS 4504 pn16 flange | Nickel Alloy 200 EN 1092-1 flat flange |

| Alloy 200 Nickel Raised Face Flanges | 200 Nickel Flat Faced Plate Flanges |

| Nickel 200 UNS N02200 Bleed Rings | Nickel Alloy 200 Class 150 Weldoflange |

| Din 2.4066 Class 150 LBS Nipo Flange | Nickel Alloy 200 Long Weld Neck Flanges |

| 200 Nickel Lap Joint Pipe Flanges | 200 Nickel PN16 Screwed Flanges |

Biggest Alloy 200 RTJ Flange Distributor. Ask free sample of Nickel DIN 2.4066 Socket Weld Flanges, Class 600 Nickel 200 Nippo Flanges Manufacturer, Global Stockist of Alloy 200 Blind Flanges. Get a Quote of ASTM B564 Nickel 200 Threaded Flanges at discounted rate

| UNS: |

N02200 |

|

Specifications: |

ASME SB-564 |

|

international Specifications: |

BS 3072, BS 3073, BS 3074, BS 3075, BS 3076, NA11 DIN 17740, 17750, 17751, 17752, 17753, 17754 Werkstoff Nr. 2.4060, 2.4066 |

Ready Stock of Alloy 200 Nickel Flange

ASTM B564 UNS N02200 Plate Flange

Nickel 200 BS 4504 Flanges

Alloy 200 Nickel Forged blind flange

200 Nickel Class 150 Flange

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Nickel 200 | 2.4066 | N02200 | NW 2200 | NA 11 | ??-2 | N-100M | Ni 99.2 |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Nickel 200 | 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 67000 , MPa – 462 | Psi – 21500 , MPa – 148 | 45 % |

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

| Nickel 200 | 0.15 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

Suppliers and Stockists of Nickel Alloy 200 WNRF Flanges, Traders of 200 Nickel Alloy SORF Flange. Delivering ASME SB564 Alloy 200 Lap Joint Flange everywhere, Specialise in manufacturing Nickel Alloy 200 Industrial Flanges. Buy 200 Nickel Alloy Forged Flanges, ASTM B564 Nickel 200 BLRF Flanges directly from manufacturers.

| Standard | Class | Diameter | Bolt Circle Diameter | Number of Bolts | Bolt Size | Diameter of Bolt Hole |

|---|---|---|---|---|---|---|

| AS 4087 | PN14 Flanges | 525 | 470 | 12 | M24 | 26 |

| PN16 Flanges | 525 | 470 | 12 | M24 | 26 | |

| PN21 Flanges | 550 | 495 | 16 | M27 | 30 | |

| PN35 Flanges | 550 | 495 | 16 | M27 | 30 | |

| AS 2129 Flanges | Table C Flanges | 525 | 470 | 12 | 22 | 26 |

| Table D Flanges | 525 | 470 | 12 | 22 | 26 | |

| Table E Flanges | 525 | 470 | 12 | 22 | 26 | |

| Table F Flanges | 550 | 495 | 16 | 25 | 30 | |

| Table H Flanges | 550 | 495 | 16 | 25 | 30 | |

| Table J Flanges | 550 | 495 | 16 | 29 | 32 | |

| ANSI B16.5 Flanges | ANSI 150 Flanges | 533 | 476 | 12 | 25 | 29 |

| ANSI 300 Flanges | 584 | 514 | 20 | 29 | 32 | |

| ANSI 600 Flanges | 603 | 527 | 20 | 38 | 41 | |

| ANSI 900 Flanges | 641 | 559 | 20 | 38 | 41 | |

| ANSI 1500 Flanges | 749 | 635 | 16 | 57 | 60 | |

| ISO 7005 (DIN) | PN6 Flanges | 490 | 445 | 12 | M20 | 22 |

| PN10 Flanges | 505 | 460 | 16 | M20 | 22 | |

| PN16 Flanges | 520 | 470 | 16 | M24 | 26 | |

| PN20 Flanges | 535 | 476 | 12 | M27 | 35 | |

| PN25 Flanges | 555 | 490 | 16 | M30 | 33 | |

| PN40 Flanges | 580 | 510 | 16 | M33 | 36 |