Nickel 201 Flanges

- Home

- Nickel 201 Flanges

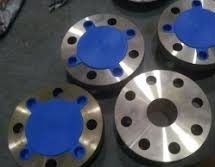

Alloy 201 Blind Flange manufacturer, Check ASTM B564 UNS N02201 Weld Neck Flange Price List

The material used to produce Nickel 201 Flanges shows true resistance, in salt solutions along with those solutions that are either acidic or alkaline in nature. Therefore nickel 201 based fittings may be used in the soap industry for the manufacturing process of soap.

Nickel 201 Flanges

Alloy 201 Blind Flange

ASTM B564 UNS N02201 Weld Neck Flange

Check Price list of Nickel 201 Blind Flange, High Pressure Nickel 201 RTJ Flange Supplier, Purchase Nickel 201 Spectacle Blind Flange at factory price.

In the presence of oxidising salt solutions, the Nickel 201 Spectacle Blind Flange is subjected to an intense corrosive attack.Since nickel 201 offers resistance against all dry gases at room temperature, this alloy grade can be conveniently utilized not only in dry chlorine but also in hydrogen chloride environments, especially at temperatures inching up to 550°C. Consequently, the Nickel 201 RTJ Flange may be used in the production of analine hydrochloride, which is an organic compound. Furthermore, the Nickel 201 Slip on Flange also can be used within the chlorination of aliphatic hydrocarbons like either methane, benzene, or ethane.

Table of Content

- What is Nickel 201 Flange?

- Price List of Alloy 201 Flange

- Spec Chart of of Nickel 201 Flanges

- Dimensions Standard of Alloy 201 Nickel Class 150 Flange

- Most famous types of ASTM B160 201 Nickel Flange

- Nickel Alloy 201 Flange Trade Names

- Nickel 201 UNS N02201 Flange Equivalent Material

- Mechanical Characteristics of Din 2.4068 Flange

- Chemical Formula of ASTM B160 UNS N02201 Flange

- Weight Of 400mm (16") 201 Nickel Flange

Although exposing the Nickel 201 Blind Flange to compounds such as chlorates ought to be kept as minimum as possible. According to the ASTM B564 specification, the Grain size, as well as the mechanical properties such as tensile strength, yield strength, along with the elongation of the alloy used to make Alloy 201 Blind Flange needs to be measured. In addition to the above mentioned values to be measured, tests such as tension test and a nondestructive ultrasonic test conducted on each specimen, which in this case is the ASTM B564 UNS N02201 Weld Neck Flange.

| Din 2.4068 Flange Size Chart | 1/2" (15 NB) to 48" (1200NB) DN10~DN5000 |

|---|---|

| Nickel Alloy 201 SORF Flange Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Nickel 201 UNS N02201 Flange Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Nickel 201 Flange Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| ASTM B160 201 Nickel Flange JIS | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K |

| UNS N02201 Flange UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

| 201 Nickel FlangeEN | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

| Most common types of Alloy 201 Nickel Flange | Forged / Threaded / Screwed / Plate |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Nickel 201 Flange Production technique |

|

| Nickel Alloy 201 Flange Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Special design |

As per your drawing AS, ANSI, BS, DIN and JIS |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

Best Price & Fast Delivery for Nickel 201 Slip on Flange, One Stop Shop For Nickel 201 Lap Joint Flange, Held wide stock of Nickel 201 Weld Neck Flange, Largest independent stockholder Nickel DIN 2.4068 Socket Weld Flanges

| Nominal Size |

Outside Diameter (OD) |

Min. Thickness (T) |

RF Dia. (R) |

No. of Bolt Holes | Diameter of Holes |

Bolt Circle (BC) |

SO Bore ID (SB) |

WN Bore ID (WB) |

Dia. Hub Base (HB) |

Dia. of Hub Top (HT) |

SO LTH (SL) |

WN LTH (WL) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1⁄2 | 3.50 | 0.38 | 1.38 | 4 | 0.62 | 2.38 | 0.88 | 0.62 | 1.19 | 0.84 | 0.56 | 1.81 |

| 3⁄4 | 3.88 | 0.44 | 1.69 | 4 | 0.62 | 2.75 | 1.09 | 0.82 | 1.50 | 1.05 | 0.56 | 2.00 |

| 1 | 4.25 | 0.50 | 2.00 | 4 | 0.62 | 3.12 | 1.36 | 1.05 | 1.94 | 1.32 | 0.62 | 2.12 |

| 11⁄4 | 4.62 | 0.56 | 2.50 | 4 | 0.62 | 3.50 | 1.70 | 1.38 | 2.31 | 1.66 | 0.75 | 2.19 |

| 11⁄2 | 5.00 | 0.62 | 2.88 | 4 | 0.62 | 3.88 | 1.95 | 1.61 | 2.56 | 1.90 | 0.81 | 2.38 |

| 2 | 6.00 | 0.69 | 3.62 | 4 | 0.75 | 4.75 | 2.44 | 2.07 | 3.06 | 2.38 | 0.94 | 2.44 |

| 21⁄2 | 7.00 | 0.81 | 4.12 | 4 | 0.75 | 5.50 | 2.94 | 2.47 | 3.56 | 2.88 | 1.06 | 2.69 |

| 3 | 7.50 | 0.88 | 5.00 | 4 | 0.75 | 6.00 | 3.57 | 3.07 | 4.25 | 3.50 | 1.12 | 2.69 |

| 31⁄2 | 8.50 | 0.88 | 5.50 | 8 | 0.75 | 7.00 | 4.07 | 3.55 | 4.81 | 4.00 | 1.19 | 2.75 |

| 4 | 9.00 | 0.88 | 6.19 | 8 | 0.75 | 7.50 | 4.57 | 4.03 | 5.31 | 4.50 | 1.25 | 2.94 |

| 5 | 10.00 | 0.88 | 7.31 | 8 | 0.88 | 8.50 | 5.66 | 5.05 | 6.44 | 5.56 | 1.38 | 3.44 |

| 6 | 11.00 | 0.94 | 8.50 | 8 | 0.88 | 9.50 | 6.72 | 6.07 | 7.56 | 6.63 | 1.50 | 3.44 |

| 8 | 13.50 | 1.06 | 10.62 | 8 | 0.88 | 11.75 | 8.72 | 7.98 | 9.69 | 8.63 | 1.69 | 3.94 |

| 10 | 16.00 | 1.12 | 12.75 | 12 | 1.00 | 14.25 | 10.88 | 10.02 | 12.00 | 10.75 | 1.88 | 3.94 |

| 12 | 19.00 | 1.19 | 15.00 | 12 | 1.00 | 17.00 | 12.88 | 12.00 | 14.38 | 12.75 | 2.12 | 4.44 |

| 14 | 21.00 | 1.31 | 16.25 | 12 | 1.12 | 18.75 | 14.14 | 13.25 | 15.75 | 14.00 | 2.19 | 4.94 |

| 16 | 23.50 | 1.38 | 18.50 | 16 | 1.12 | 21.25 | 16.16 | 15.25 | 18.00 | 16.00 | 2.44 | 4.94 |

| 18 | 25.00 | 1.50 | 21.00 | 16 | 1.25 | 22.75 | 18.18 | 17.25 | 19.88 | 18.00 | 2.62 | 5.44 |

| 20 | 27.50 | 1.62 | 23.00 | 20 | 1.25 | 25.00 | 20.20 | 19.25 | 22.00 | 20.00 | 2.81 | 5.62 |

| 22 | 29.50 | 1.75 | 25.25 | 20 | 1.38 | 27.25 | 22.22 | 21.25 | 24.25 | 22.00 | 3.07 | 5.82 |

| 24 | 32.00 | 1.81 | 27.25 | 20 | 1.38 | 29.50 | 24.25 | 23.25 | 26.12 | 24.00 | 3.19 | 5.94 |

| Din 2.4068 Flange | Nickel 201 Blind Flange |

| Nickel Alloy 201 Slip on Flange | UNS N02201 Threaded Flange |

| Din 2.4068 Reducing Flange | Alloy 201 Socket Weld Flange |

| UNS N02201 Weld Neck Flanges | Nickel 201 Lap Joint Flanges |

| ASTM B160 201 Nickel Long Weld Neck Flanges | Din 2.4068 Spectacle Blind Flanges |

| UNS N02201 Spades & Ring Spacers | Alloy 201 Nipoflange |

| Nickel 201 5D Weldoflange | ASTM B160 UNS N02201 Flange Outlet |

| Din 2.4068 Forged Flanges | 201 Nickel Plate Flange |

| Din 2.4068 Ring Type Joint Flanges | Alloy 201 Raised Face Flanges |

| Nickel 201 Tongue and Groove Flanges | 201 Nickel Male and Female Flange |

| UNS N02201 Reducing Flanges | Din 2.4068 ASME B16.5 Flanges |

| ASTM B160 UNS N02201 Flanges | Nickel Alloy 201 BS 10 Flanges |

| Nickel 201 BS 4504 Flanges | Alloy 201 EN 1092-1 Flanges |

| ASTM B160 201 Nickel SORF Flange | Din 2.4068 BLRF Flange |

| ASTM B160 UNS N02201 WNRF Flange | Nickel Alloy 201 RTJ Flange |

| Nickel 201 Series a Lap Joint Ring Flange | Alloy 201 Class 300 threaded flange |

| Din 2.4068 PN16 blind flange | Nickel 201 UNS N02201 Forged Socket Weld Pipe Flange |

| Nickel 201 Class 300 slip on flange | UNS N02201 Slip On Weld Flange |

| Nickel Alloy 201 Forged steel slip on flanges | Nickel Alloy 201 Race face slip on flange |

| ASTM B160 UNS N02201 SWRF Flange | Nickel 201 UNS N02201 Forged blind flange |

| Nickel 201 groove weld neck flange | ASTM B160 201 Nickel Socket Weld Hub Flange |

| ASTM B160 UNS N02201 threaded lap joint flange | Nickel 201 UNS N02201 Slip On Integral flange |

| Nickel 201 Forged integral puddle flange | Nickel Alloy 201 table e long weld neck |

| Din 2.4068 Class 150 LBS Flange | 201 Nickel PN10 Forged Flanges |

| Nickel 201 RTJ Flanges | UNS N02201 PN10 Plate Flanges |

| Din 2.4068 Tongue & Groove Flanges | Nickel 201 Reducing Flanges |

| Nickel Alloy 201 Class 150 reducing threaded flange | Nickel Alloy 201 Class 150 Pipe Flange |

| ASTM B160 201 Nickel Class 150 Flange | Nickel 201 UNS N02201 Pipe Flanges |

| Din 2.4068 BS 10 Flanges | Alloy 201 Nickel Class 150 Tongue & Groove Flanges |

| Nickel Alloy 201 BS 4504 pn16 flange | Din 2.4068 EN 1092-1 flat flange |

| Nickel 201 UNS N02201 Raised Face Flanges | ASTM B160 201 Nickel Flat Faced Plate Flanges |

| Alloy 201 Bleed Rings | Din 2.4068 Class 150 Weldoflange |

| Nickel Alloy 201 Class 150 LBS Nipo Flange | Din 2.4068 Long Weld Neck Flanges |

| ASTM B160 201 Nickel Lap Joint Pipe Flanges | ASTM B160 201 Nickel PN16 Screwed Flanges |

Distributing globally Nickel 201 Nippo Flanges at best prices. ASME SB564 Alloy 201 Lap Joint Flange are available in different sizes to fulfill any requirement, One of India’s largest Manufacturer ASTM B564 Nickel 201 BLRF Flanges, Suppliers and Stockists of Alloy 201 RTJ Flange. Schedule 80 Nickel Alloy 201 Industrial Flanges are ready to dispatch if ordered today.

| UNS: |

N02201 |

|

Specifications: |

ASME SB-564 |

|

international Specifications: |

BS 3072, BS 3073, BS 3074, BS 3075, BS 3076, NA11 DIN 17740, 17750, 17751, 17752, 17753, 17754 Werkstoff Nr. 2.4060, 2.4066 |

Exclusive Ready Stock of Nickel 201 UNS N02201 Flange

Nickel 201 RTJ Flanges

Nickel 201 Reducing Flanges

ASTM B160 201 Nickel Socket Weld Hub Flange

Nickel 201 Class 300 slip on flange

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Nickel 201 | 2.4068 | N02201 | NW 2201 | NA 12 | ??-2 | – | LC-Ni 99 |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Nickel 201 | 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 67000 , MPa – 462 | Psi – 21500 , MPa – 148 | 45 % |

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

| Nickel 201 | 0.02 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

Best Price & Fast Delivery for Alloy 201 Blind Flanges, Own stockyard of Nickel UNS N02201 Pipe Flanges, Biggest supplier of small-quantity ASTM B564 Nickel 201 Threaded Flanges, Largest Manufacturer 201 Nickel Alloy Forged Flanges. 201 Nickel Alloy SORF Flange, Contact us today to buy Nickel Alloy 201 WNRF Flanges at 10% discounted rate.

| Standard | Class | Diameter | Bolt Circle Diameter | Number of Bolts | Bolt Size | Diameter of Bolt Hole |

|---|---|---|---|---|---|---|

| AS 4087 | PN14 Flange | 580 | 521 | 12 | M24 | 26 |

| PN16 Flange | 580 | 521 | 12 | M24 | 26 | |

| PN21 Flange | 610 | 552 | 20 | M27 | 30 | |

| PN35 Flange | 610 | 552 | 20 | M27 | 30 | |

| AS 2129 Flanges | Table C Flange | 580 | 521 | 12 | 22 | 26 |

| Table D Flange | 580 | 521 | 12 | 22 | 26 | |

| Table E Flange | 580 | 521 | 12 | 22 | 26 | |

| Table F Flange | 610 | 552 | 20 | 25 | 30 | |

| Table H Flange | 610 | 552 | 20 | 25 | 30 | |

| Table J Flange | 610 | 552 | 20 | 29 | 33 | |

| ANSI B16.5 Flanges | ANSI 150 Flange | 597 | 540 | 16 | 25 | 29 |

| ANSI 300 Flange | 648 | 572 | 20 | 32 | 35 | |

| ANSI 600 Flange | 686 | 603 | 20 | 38 | 41 | |

| ANSI 900 Flange | 705 | 616 | 20 | 41 | 44 | |

| ANSI 1500 Flange | 826 | 705 | 16 | 64 | 67 | |

| ISO 7005 (DIN) | PN6 Flange | 540 | 495 | 16 | M20 | 22 |

| PN10 Flange | 565 | 515 | 16 | M24 | 26 | |

| PN16 Flange | 580 | 525 | 16 | M27 | 30 | |

| PN20 Flange | 600 | 540 | 16 | M27 | 29.5 | |

| PN25 Flange | 620 | 550 | 16 | M33 | 36 | |

| PN40 Flange | 660 | 585 | 16 | M36 | 39 |