Incoloy 800 Pipe Fittings

- Home

- Incoloy 800 Pipe Fittings

Manufacturer of Alloy 800H/ 800HT Elbow, Check ASME B16.9 Buttweld Reducing Tee Price List, Refer Dimensions of ASTM B366 UNS N08800 Fittings

Regularly dual certified, the Alloy 800H/ 800HT Elbow is a superior and versatile fitting, as compared to Alloy grade 800 in terms of the former having enhanced creep and stress rupture properties. ASME B16.9 Buttweld Reducing Tee is seen in many places since it is considered to be well suited for use in applications that involve long periods of exposure to elevated temperature conditions, where properties like its resistance to high temperature corrosion along with resistance to oxidation and to carburization. Quite a few of our buyers who prefer using the Incoloy 800H Pipe Fittings belong to fields such as Hydrocarbon processing, in addition to heat treatment furnaces and power generation.

Incoloy 800 Pipe Fittings

Alloy 800H/ 800HT Elbow

ASME B16.9 Buttweld Reducing Tee

Looking to Buy Incoloy 800H Pipe Fittings from Suppliers, Check Incoloy 800 Elbow Dimensions & Weight charts, Ask For ready stock of Incoloy 800H Tee.

While the addition of high amounts of nickel and chromium to these Incoloy 800 Pipe Fittings during their manufacture makes them resilient while providing enhanced resistance to sulfidation. Although an Incoloy 800 Elbow tends to exhibit resistance to nitriding due to the addition of nickel in its alloy, in contrast to a nickel alloy Inconel 600, this property is not as predominant as the latter. The dissimilarity between Incoloy 800Ht Reducer fitting and alloy 800H is that alloy 800Ht has been manufactured with a controlled content of both aluminium as well as titanium.

Table of Content

- What is 800 Incoloy Fittings?

- Specification List of Incoloy 800 Pipe Fittings

- Price List of 800 Incoloy Pipe Fittings

- Different types of Nickel Alloy 800 Fittings

- Check Stock list of Incoloy 800 Fittings

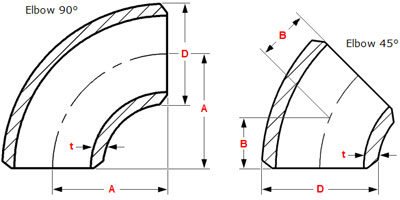

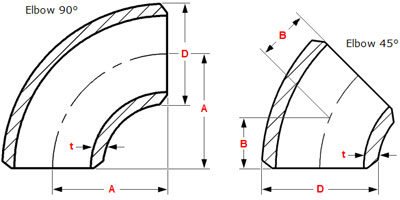

- Dimensions & Weight Chart of Incoloy 800Ht 45 deg elbow

- Mechanical Analysis of ASTM B366 UNS N08800 Pipe Fittings

- Chemical Composition of Incoloy alloy 800H Buttweld Fittings

- Nickel 800 Fittings Equivalent Grade Material

- Trade Names of Incoloy 800 ASTM B366 Fittings

- Available Testing of Incoloy 800H Fittings

- Nickel 800 Fittings Dimensions

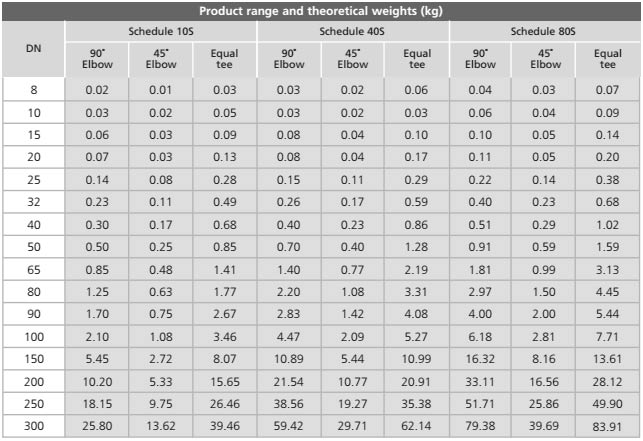

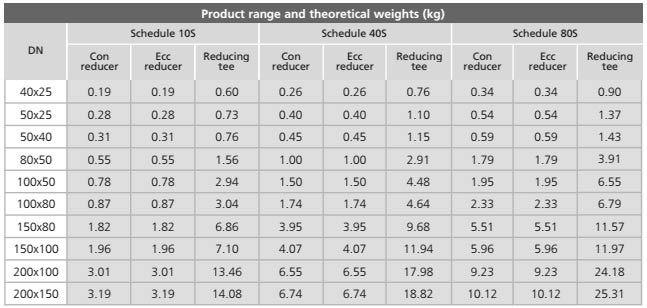

- Weight Chart of Incoloy 800Ht Buttweld Fittings

- Dimensions of ASTM B366 UNS N08800 Reducer

Incoloy 800 Fittings

On the other hand, the difference between alloy 800 and Incoloy 800H Tee is the added carbon content, the former alloy tends to have a higher content of carbon in its alloy. Trade names for Alloy 800, apart from Incoloy 800H, include the - Ferrochronin 800H/HT or Nickelvac 800H/HT, and Nicrofer 3220 as well.

Incoloy 825 Butt Weld Pipe Fittings is a widely used material for construction of equipment requiring corrosion resistance, heat resistance, strength, and stability for service up to 1500°F (816°C). ASTM B366 Inconel 825 Pipe Fittings offers general corrosion resistance to many aqueous media and, by virtue of its content of nickel, resists stress corrosion cracking.

| Grade | Monel 400 / UNS N04400 |

| size | Seamless Butt Weld Fittings: 1/2" - 10" Welded Butt Weld Fittings: 1/2" - 48" |

|---|---|

| Type | DN15-DN1200 |

| Connection | Welding |

| Form | 90 Elbow, 45 Elbow, Long Radius Elbow, Short Radius Elbow, Concentric Reducer, Eccentric Reducer, Equal Tee, Unequal Tee, Lateral Tee, Cross, Bends 1.5d, 3d, 5d, 10d, U bend, 180 Deg Bend, Short Stub End, Long stub end, End Cap, Dish Cap |

| Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 |

| Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| Bending Radius | R= 2D, 6D, 1D, 5D, 8D, 3D, 10D or Custom MSS Sp-43 Stainless Steel Pipe Fitting |

| Size Range | ½" NB to 24" NB in Sch 10s, 40s, 80s, 160s, XXS. (DN6~DN100) ASTM A403 Stainless Steel Buttweld Fitting |

| Manufacturing process | Push, Press, Forge, Cast, etc. |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Origin & Mills | Japanese, Indian, USA, Korean, European, Ukraine, Russian |

| Key markets and industries |

|

| Specialized manufacturer of | 90º Elbows, 45º Elbows, Tees, Crosses, Reducers, Pipe Cap, Stub End, Pipe Bend |

| Application & uses |

|

| We provide Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

| Price of Incoloy 800 Pipe Fittings | 800 Incoloy Fittings Price in India (INR) | 800 Incoloy Fittings Price in USD | 800 Incoloy Fittings Price in UAE Dirham |

|---|---|---|---|

| Cost of Alloy 800 Class 3000 1/8″ Elbow in India | 49381.21 | $710.7 | UAE Dirham 2610.44 |

| 800 Incoloy Alloy 1/8″ Tee in Mumbai | 13347.59 | $192.1 | UAE Dirham 705.59 |

| ASME SB366 Incoloy 800 1-1/4″ 45° Elbow | 17009.32 | $244.8 | UAE Dirham 899.16 |

STUB END b366 800 Alloy CL600 RF ASME B16.9 1-1/2" SCH80S pipe fittings

ASME SB366 UNS N08800 Short Radius Elbow

Incoloy 800 Reducer

Incoloy WERKSTOFF NR. 1.4876 Pipe Bend

UNS N08800 Eccentric Reducer

4 inch Incoloy 800 pipe fittings

Incoloy 800 Fittings

UNS N08800 Long Radius Elbow

ASME SB366 Incoloy 800 Eccentric Reducer

Alloy 800 butt weld seamless pipe fittings 2" SCH40 90 elbow

UNS N08800 Incoloy Short Stub End

MSS-SP-43 Incoloy 800 Straight Tees

ASTM B366 Alloy 800 Piggable Bend

ANSI B16.9 Incoloy Alloy 800 Pipe Cap

800 Incoloy Pipe Reducer 2"*1" SCH40 Seamless Fittings

Incoloy 800 Stub End

800 Incoloy Pipe Bend

4X3 inch std40 Incoloy 800 astm b16.9 concentric eccentric reducer

Alloy 800 End Cap

Incoloy JIS NCF 800 Concentric Reducer

Incoloy 800 Tee

DIN 1.4876 Fittings

Incoloy 800 Elbow

ASTM B366 UNS N08800 Straight Tees

Asme B16.9 Incoloy 800 Cross

Incoloy Din 1.4876 Equal Tees

Incoloy 800h Bend

Astm B366 Incoloy 800 Buttweld Elbow

Incoloy Uns N08800 Reducer

800ht Incoloy Buttweld Pipe Fittings

Incoloy 800 Stubends

800 Incoloy Pipe Nipple

Incoloy Uns N08810 Pipe Cap

800 Incoloy Welded Pipe Fittings

Incoloy Din 1.4958 Lr Bends

800ht Lr Elbow

Leading Incoloy 800Ht Reducer Stockist, Check available sizes of Incoloy 800 Stub End, Get a best quote for Alloy 800 Fittings from leading manufacturers, We have Global sales network for Incoloy 800H Pipe Cap

| 800 Incoloy Fittings | Incoloy 800 Pipe Fitting |

| Incoloy 800Ht 90 Degree Elbow | ASTM B366 UNS N08800 End Cap |

| Incoloy 800 ASTM B366 45 Degree Elbow | Incoloy alloy 800H Buttweld Fitting |

| Alloy 800H 1D Elbow | Nickel 800 Short Stub End |

| Incoloy alloy 800H Stub End | 800 Incoloy Pipe Cap |

| Incoloy 800Ht 3D Elbow | Nickel Alloy 800 End Cap |

| Incoloy 800 5D Elbow | Nickel Alloy 800 Reducer |

| 800 Incoloy Buttweld Fittings | ASTM B366 UNS N08800 Pipe Bend |

| Incoloy 800 ASTM B366 Pipe Fittings | Alloy 800H Long Stub End |

| Incoloy 800/H/HT Pipe Fittings | Incoloy 800h Pipe Cap |

| Incoloy 800 Butt Weld Pipe Fittings | Astm B564 Incoloy 800ht Forged Threaded Elbow |

| Incoloy 800H Butt Weld Pipe Fittings | Incoloy Uns N08800 High Pressure Forged Fittings |

| Incoloy 800HT Butt Weld Pipe Fittings | 800h Incoloy Full Couplings |

| Alloy 800 Pipe Fittings | Asme B16.11 Incoloy 800ht Union |

| Alloy 800H Pipe Fittings | Incoloy Din 1.4858 Street Elbow |

| Alloy 800HT Pipe Fittings | 800 Incoloy Threaded Fittings |

| Incoloy 800 Butt Weld Fittings | Uns N08810 Bushings |

| Incoloy 800H Butt Weld Fittings | Incoloy Uns N08811 Pipe Nipple |

| Incoloy Din 1.4876 Equal Tees | Incoloy Din 1.4859 Reducing Insert |

| Incoloy alloy 800H Eccentric Reducer | Alloy 800H Long Radius Elbow |

| Nickel Alloy 800 Concentric Reducer | Incoloy 800Ht Short Radius Elbow |

| Incoloy 800 ASTM B366 Equal Cross | 800 Incoloy Pipe Cap |

| ASTM B366 UNS N08800 Lateral Tee | Incoloy 800Ht Cross Tee |

| Nickel 800 Reducing Cross | Incoloy alloy 800H Equal Cross |

| Incoloy 800 Equal Tee | Nickel Alloy 800 Stub End |

| ASTM B366 UNS N08800 Concentric Reducer | Incoloy 800 ASTM B366 5D Elbow |

Our ASTM B366 800 Incoloy Eccentric Reducer are very cost-effective, Ask free sample of Alloy 800 Short Radius Elbow. Purchase 800HT Incoloy Alloy End Cap at reasonable price. Top-notch stockist of Incoloy UNS N08800 45 Degree Elbow, Incoloy 800HT Pipe Fittings widely used in Chemical Industry

Exclusive Ready Stock of Nickel Alloy 800 Fittings

Incoloy alloy 800H Buttweld Fitting

Incoloy 800 ASTM B366 Pipe Fittings

Nickel Alloy 800 Concentric Reducer

Incoloy alloy 800H Equal Cross

| NPS | O.D.D | 90 degrees Long Radius Elbow Center-to-EndA | 45 degrees Long Radius Elbow Center-to-EndB | 90 degrees 3D Elbow Center-to-EndA | 45 degrees 3D Elbow Center-to-EndB |

| 1/2 | 21.3 | 38 | 16 | – | – |

| 3/4 | 26.7 | 38 | 19 | 57 | 24 |

| 1 | 33.4 | 38 | 22 | 76 | 31 |

| 1¼ | 42.2 | 48 | 25 | 95 | 39 |

| 1½ | 48.3 | 57 | 29 | 114 | 47 |

| 2 | 60.3 | 76 | 35 | 152 | 63 |

| 2½ | 73 | 95 | 44 | 190 | 79 |

| 3 | 88.9 | 114 | 51 | 229 | 95 |

| 3½ | 101.6 | 133 | 57 | 267 | 111 |

| NPS | O.D.D | 90 degrees Long Radius Elbow Center-to-EndA | 45 degrees Long Radius Elbow Center-to-EndB | 90 degrees 3D Elbow Center-to-EndA | 45 degrees 3D Elbow Center-to-EndB |

|

|||||

| NPS | O.D.D | 90 degrees Long Radius Elbow Center-to-EndA | 45 degrees Long Radius Elbow Center-to-EndB | 90 degrees 3D Elbow Center-to-EndA | 45 degrees 3D Elbow Center-to-EndB |

| 4 | 114.3 | 152 | 64 | 305 | 127 |

| 5 | 141.3 | 190 | 79 | 381 | 157 |

| 6 | 168.3 | 229 | 95 | 457 | 189 |

| 8 | 219.1 | 305 | 127 | 610 | 252 |

| 10 | 273 | 381 | 159 | 762 | 316 |

| 12 | 323.8 | 457 | 190 | 914 | 378 |

| 14 | 355.6 | 533 | 222 | 1067 | 441 |

| 16 | 406.4 | 610 | 254 | 1219 | 505 |

| 18 | 457 | 686 | 286 | 1372 | 568 |

| 20 | 508 | 762 | 318 | 1524 | 632 |

| 22 | 559 | 838 | 343 | 1676 | 694 |

| 24 | 610 | 914 | 381 | 1829 | 757 |

| 26 | 660 | 991 | 406 | 1981 | 821 |

| 28 | 711 | 1067 | 438 | 2134 | 883 |

| 30 | 762 | 1143 | 470 | 2286 | 964 |

| 32 | 813 | 1219 | 502 | 2438 | 1010 |

| 34 | 864 | 1295 | 533 | 2591 | 1073 |

| 36 | 914 | 1372 | 565 | 2743 | 1135 |

| 38 | 965 | 1448 | 600 | 2896 | 1200 |

| 40 | 1016 | 1524 | 632 | 3048 | 1264 |

| 42 | 1067 | 1600 | 660 | 3200 | 1326 |

| 44 | 1118 | 1676 | 695 | 3353 | 1389 |

| 46 | 1168 | 1753 | 727 | 3505 | 1453 |

| 48 | 1219 | 1829 | 759 | 3658 | 1516 |

| NPS | O.D.D | 90 degrees Long Radius Elbow Center-to-EndA | 45 degrees Long Radius Elbow Center-to-EndB | 90 degrees 3D Elbow Center-to-EndA | 45 degrees 3D Elbow Center-to-EndB |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 800 / 800H / 800HT | 7.94 g/cm3 | 1385 °C (2525 °F) | Psi – 75,000 , MPa – 520 | Psi – 30,000 , MPa – 205 | 30 % |

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr | Al | Ti |

| 800 | 0.10 max | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

| 800H | 0.05 – 0.10 | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

| 800HT | 0.06 – 0.10 | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60? | 0.15 – 0.60? |

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN | OR |

| Incoloy 800 | 1.4876 | N08800 | NCF 800 | NA 15 | ЭИ670 | Z8NC32-21 | X10NiCrAlTi32-20 | XH32T |

| Incoloy 800H | 1.4958 / 1.4876 | N08810 | NCF 800H | NA 15(H) | ЭИ670 | Z8NC33-21 | X5NiCrAlTi31-20 | XH32T |

| Incoloy 800HT | 1.4859 / 1.4876 | N08811 | NCF 800HT | NA 15(HT) | ЭИ670 | – | X8NiCrAlTi32-21 | XH32T |

Largest supplier of small-quantity Incoloy Alloy 800 Equal Tee, Best Price & Fast Delivery for Incoloy DIN 1.4876 Cross, Own stockyard of Incoloy 800H Pipe Elbow, Largest Manufacturer ASTM B366 800H Incoloy End Cap. 800H Incoloy Reducer, Contact us today to buy Alloy 800HT Long Stub End at 10% discounted rate.

| UNS: |

N08800 |

|

Specifications: |

ASTM B407, ASTM B829, ASTM B514, ASTM B775, ASTM B515, ASTM B751 |

|

international Specifications: |

BS3 3074NA15, ISO 6207, DIN 17459, VdTüV 412 & 434 |

- Positive Material Identification - PMI Testing

- Micro Test

- Intergranular Corrosion (IGC) Test

- Flaring Test

- Chemical Analysis - Spectro Analysis

- Mechanical Testing Such as Tensile, Elongation

- Flattening Test

- Macro Test

- Hardness Test

- Pitting Resistance Test

- Hydrostatic Test

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

- Radiography Test

- Dye Penetrant Test (DP Test)

- Impact Test

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Ultra Sonic Test (UT)

- Eddy Current Testing

- Bend Test

| Nominal Pipe Size |

Outside Diameter |

Reducers | ||

|---|---|---|---|---|

|

Reduced from

(inches) |

(mm)

|

(inches)

|

Reduced to

(inches) |

Concentric & Eccentric Length

(inches) |

|

1/2

|

21.3

|

0.840

|

1/4

|

1 1/2

|

|

3/8

|

1 1/2

|

|||

|

3/4

|

26.7

|

1.050

|

3/8

|

2

|

|

1/2

|

2

|

|||

|

1

|

33.4

|

1.315

|

3/8

|

2

|

|

1/2

|

2

|

|||

|

3/4

|

2

|

|||

|

1 1/4

|

42.2

|

1.660

|

1/2

|

2

|

|

3/4

|

2

|

|||

|

1

|

2

|

|||

|

1 1/2

|

48.3

|

1.900

|

1/2

|

2 1/2

|

|

3/4

|

2 1/2

|

|||

|

1

|

2 1/2

|

|||

|

1 1/4

|

2 1/2

|

|||

|

2

|

60.3

|

2.375

|

3/4

|

3

|

|

1

|

3

|

|||

|

1 1/4

|

3

|

|||

|

1 1/2

|

3

|

|||

|

2 1/2

|

73.0

|

2.875

|

1

|

3 1/2

|

|

1 1/4

|

3 1/2

|

|||

|

1 1/2

|

3 1/2

|

|||

|

2

|

3 1/2

|

|||

|

3

|

88.9

|

3.500

|

1

|

3 1/2

|

|

1 1/2

|

3 1/2

|

|||

|

2

|

3 1/2

|

|||

|

2 1/2

|

3 1/2

|

|||

|

3 1/2

|

101.6

|

4.000

|

1 1/4

|

4

|

|

1 1/2

|

4

|

|||

|

2

|

4

|

|||

|

2 1/2

|

4

|

|||

|

3

|

4

|

|||

|

4

|

114.3

|

4.500

|

1 1/2

|

4

|

|

2

|

4

|

|||

|

2 1/2

|

4

|

|||

|

3

|

4

|

|||

|

3 1/2

|

4

|

|||

|

5

|

141.3

|

5.563

|

2

|

5

|

|

2 1/2

|

5

|

|||

|

3

|

5

|

|||

|

3 1/2

|

5

|

|||

|

4

|

5

|

|||

|

6

|

168.3

|

6.625

|

2 1/2

|

5 1/2

|

|

3

|

5 1/2

|

|||

|

3 1/2

|

5 1/2

|

|||

|

4

|

5 1/2

|

|||

|

5

|

5 1/2

|

|||

|

8

|

219.1

|

8.625

|

3

|

6

|

|

3 1/2

|

6

|

|||

|

4

|

6

|

|||

|

5

|

6

|

|||

|

6

|

6

|

|||

|

10

|

273.1

|

10.750

|

4

|

7

|

|

5

|

7

|

|||

|

6

|

7

|

|||

|

8

|

7

|

|||

|

12

|

323.9

|

12.750

|

5

|

8

|

|

6

|

8

|

|||

|

8

|

8

|

|||

|

10

|

8

|

|||