Titanium Grade 2 Pipe Fittings

- Home

- Titanium Grade 2 Pipe Fittings

View Titanium Grade 2 Pipe Fittings Weight Chart, Manufacturer of ASTM B363 UNS R50400 Buttweld Elbow

Grade 2 is a commercially pure titanium grade. Stronger than titanium grade 1, but it is softer than its commercially pure counterpart grades 3 & 4. The Titanium Grade 2 Pipe fittings can be manufactured using ASTM B363, which has been intended for use in both general corrosion resistance as well as in elevated temperature applications. For the reason that titanium has the ability to withstand high temperature, the specified ASTM B363 UNS R50400 Buttweld Elbow, considered to be one of the more popular fittings benefits industries like aerospace, automobile as well as the marine engineering industry.

Titanium Grade 2 Pipe Fittings

Titanium Gr 2 Stub end

ASTM B363 UNS R50400 Buttweld Elbow

High Pressure Titanium Grade 2 Elbow Supplier, Check Price list of Titanium Grade 2 Reducer, Purchase Titanium Grade 2 Tee at factory price.

Also since grade 2 has good fabricability properties, the Titanium Grade 2 Elbow can be manufactured in either a 90 degree, 45 degrees, a 22.5 degree or it can be produced in any dimension depending on the requirements desired by the buyer. This is because grade 2 elbows prove to be an option that permits flexibility, in terms of change in direction of the flow of media.

Table of Content

- What is Titanium 3.7165 Fittings?

- Titanium 3.7165 Pipe Fittings Price List

- Specification Format of Titanium Grade 2 Pipe Fittings

- Most commonly used Titanium Grade 2 Fittings Types

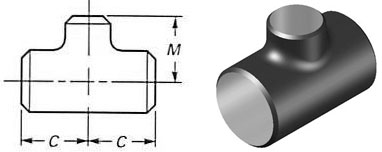

- Weight & Dimensions of Titanium gr 2 Reducing Tee

- Mechanical Analysis of Grade 2 Pure Titanium Pipe Fittings

- Composition Chart of ASTM B363 Titanium Grade 2 Buttweld Fittings

- Titanium Alloy Grade 2 Fittings Equivalent Material

- international Trade Names of Gr 2 Titanium Fittings

Often used as a substitute for welded flanges, a Titanium Gr 2 Stub end is used in times when the support of a rotating backup flange is desired. A short piece of pipe, the Titanium Grade 2 Tee is what connects the pipeline at a 90 degree angle. Typically the length of the reduction in a Titanium Grade 2 Reducer is equal to the average of the larger as well as the smaller pipe diameters. Although the ASME B16.9 Reducer is usually concentric, but on some occasions, an eccentric reducer can be used if needed in order to maintain the same top or the bottom of pipe level.

| Grade 2 Titanium Fittings Specifications | ASTM B363 / ASME SB363 |

|---|---|

| Titanium gr 2 Pipe Fittings size | Titanium Grade 2 Seamless Butt Weld Fittings: 1/2" - 10" Titanium 3.7165 Welded Butt Weld Fittings: 1/2" - 48" |

| Gr 2 Titanium Pipe Fittings Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 |

| Ti Alloy Grade 2 Fittings Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| Titanium Grade 2 Pipe fittings Types |

|

| Titanium Grade 2 FittingsType | DN15-DN1200 |

| ASTM B363 Titanium Grade 2 Buttweld Fitting Connection | Welding |

| Bending Radius | R= 2D, 6D, 1D, 5D, 8D, 3D, 10D or Custom Titanium UNS R50400 Pipe Fitting |

| Size Range | ½" NB to 24" NB in Sch 10s, 40s, 80s, 160s, XXS. (DN6~DN100) Grade 2 Pure Titanium Buttweld Fitting |

| Grade 2 Titanium Elbows | Angle : 22.5 deg, 30deg, 45 deg, 90 deg, 180 deg, 1.0D, 1.5D, 2.0D, 2.5D, 3D, 4D, 5D, 6D, 7D-40D . Standard: ASME B16.9, ASME B16.28, ASME B16.25, MSS SP-75 DIN2605 JISB2311 JISB2312 JISB2313, BS, GB, ISO |

| Titanium Grade 2 Fittings Manufacturing process | Push, Press, Forge, Cast, etc. |

| Titanium Grade 2 Buttweld Pipe Fittings Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| We provide Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

Held wide stock of ASME B16.9 Reducer, Best Price & Fast Delivery for Titanium Grade 2 Pipe Cap, One Stop Shop For Titanium Gr 2 Pipe Elbow, Largest independent stockholder Titanium Gr 2 45 degree Elbow

| Titanium 3.7165 Fittings | Titanium Grade 2 Pipe Fitting |

| Titanium UNS R50400 90 Degree Elbow | Grade 2 Pure Titanium End Cap |

| Gr 2 Titanium 45 Degree Elbow | ASTM B363 Titanium Grade 2 Buttweld Fitting |

| Ti Alloy Grade 2 1D Elbow | Titanium Alloy Grade 2 Short Stub End |

| ASTM B363 Titanium Grade 2 Stub End | Titanium 3.7165 Pipe Cap |

| Titanium gr 2 3D Elbow | Grade 2 Titanium End Cap |

| Titanium Grade 2 5D Elbow | Grade 2 Titanium Reducer |

| Titanium 3.7165 Buttweld Fittings | Grade 2 Pure Titanium Pipe Bend |

| Gr 2 Titanium Pipe Fittings | Ti Alloy Grade 2 Long Stub End |

| ASTM B363 Titanium Grade 2 Eccentric Reducer | Ti Alloy Grade 2 Long Radius Elbow |

| Grade 2 Titanium Concentric Reducer | Titanium UNS R50400 Short Radius Elbow |

| Gr 2 Titanium Equal Cross | Titanium 3.7165 Pipe Cap |

| Grade 2 Pure Titanium Lateral Tee | Titanium gr 2 Cross Tee |

| Titanium Alloy Grade 2 Reducing Cross | ASTM B363 Titanium Grade 2 Equal Cross |

| Titanium Grade 2 Equal Tee | Grade 2 Titanium Stub End |

| Grade 2 Pure Titanium Concentric Reducer | Gr 2 Titanium 5D Elbow |

Check Availability of Titanium Gr 2 Alloy End Cap, Ask for free sample of ASTM B363 Titanium Gr 2 90 degree Elbow. Titanium Gr 2 Reducer are available in different sizes & schedules. Buy directly from Titanium Gr 2 Lateral Tee stockist, Top-notch supplier of Titanium Alloy Gr 2 Pipe bend

Common Types of Grade 2 Titanium Fittings

Titanium UNS R50400 Short Radius Elbow

ASTM B363 Titanium Grade 2 Stub End

Titanium Alloy Grade 2 Reducing Cross

Grade 2 Titanium Concentric Reducer

| Nominal Pipe Size | Outside diameter

at bevel |

Center-to-End | |||

|---|---|---|---|---|---|

| Run | Outlet | Run | Outlet | Run (C) | Outlet (M) |

| 1/2″ | 1/4″

3/8″ |

21.3 | 13.7

17.3 |

25 | 25 |

| 3/4″ | 3/8″

1/2″ |

26.7 | 17.3

21.3 |

29 | 29 |

| 1″ | 1/2″

3/4″ |

33.4 | 21.3

26.7 |

38 | 38 |

| 1 1/4″ | 1/2″

3/4″ 1″ |

42.2 | 21.3

26.7 33.4 |

48 | 48 |

| 1 1/2″ | 1/2″

3/4″ 1″ 1 1/4″ |

48.3 | 21.3

26.7 33.4 42.2 |

57 | 57 |

| 2″ | 3/4″

1″ 1 1/4″ 1 1/2″ |

60.3 | 26.7

33.4 42.2 48.3 |

64 | 44

51 57 60 |

| 2 1/2″ | 1″

1 1/4″ 1 1/2″ 2″ |

73.0 | 33.4

42.2 48.3 60.3 |

76 | 57

64 67 70 |

| 3″ | 1 1/4″

1 1/2″ 2″ 2 1/2″ |

88.9 | 42.2

48.3 60.3 73.0 |

86 | 70

73 76 83 |

| 3 1/2″ | 1 1/2″

2″ 2 1/2″ 3″ |

101.6 | 48.3

60.3 73.0 88.9 |

95 | 79

83 89 92 |

| 4″ | 1 1/2″

2″ 2 1/2″ 3″ 3 1/2″ |

114.3 | 48.3

60.3 73.0 88.9 101.6 |

105 | 86

89 95 98 102 |

| 5″ | 2″

2 1/2″ 3″ 3 1/2″ 4″ |

141.3 | 60.3

73.0 88.9 101.6 114.3 |

124 | 105

108 111 114 117 |

| 6″ | 2 1/2″

3″ 3 1/2″ 4″ 5 |

168.3 | 73.0

88.9 101.6 114.3 141.3 |

143 | 121

124 127 130 137 |

| 8″ | 3 1/2″

4″ 5″ 6″ |

219.1 | 101.6

114.3 141.3 168.3 |

178 | 152

156 162 168 |

| 10″ | 4″

5″ 6″ 8″ |

273.0 | 114.3

141.3 168.3 219.1 |

216 | 184

191 194 203 |

| 12″ | 5″

6″ 8″ 10″ |

323.8 | 141.3

168.3 219.1 273.0 |

254 | 216

219 229 241 |

| 14″ | 6″

8″ 10″ 12″ |

355.6 | 168.3

219.1 273.0 323.8 |

279 | 238

248 257 270 |

| 16″ | 6″

8″ 10″ 12″ 14″ |

406.4 | 168.3

219.1 273.0 323.8 355.6 |

305 | 264

273 283 295 305 |

| 18″ | 8″

10″ 12″ 14″ 16″ |

457.0 | 219.1

273.0 323.8 355.6 406.4 |

343 | 298

308 321 330 330 |

| 20″ | 8″

10″ 12″ 14″ 16″ 18″ |

508.0 | 219.1

273.0 323.8 355.6 406.4 457.0 |

381 | 324

333 346 356 356 368 |

| 22″ | 10″

12″ 14″ 16″ 18″ 20″ |

559.0 | 273.0

323.8 355.6 406.4 457.0 508.0 |

419 | 359

371 381 381 394 406 |

| 24″ | 10″

12″ 14″ 16″ 18″ 20″ 22″ |

610.0 | 273.0

323.8 355.6 406.4 457.0 508.0 559.0 |

432 | 384

397 406 406 419 432 432 |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Titanium Gr. 2 | 4.5 g/cm3 | 1665 °C (3030 °F) | Psi – 49900 , MPa – 344 | Psi – 39900 , MPa – 275 | 20 % |

| Grade | Ti | C | Fe | H | N | O | Al | V |

| Ti Grade2 | 99.2 min | 0.1 max | 0.3 max | 0.015 max | 0.03 max | 0.25 max | – | – |

| STANDARD | WERKSTOFF NR. | UNS |

| Titanium Gr. 2 | 3.7035 | R50400 |

Largest distributor of small-quantity Titanium Gr 2 Buttweld Fittings, Most recognized manufacturer of DIN 3.7035 Tee, Global sales network of ASME SB363 Titanium Gr 2 Long Stub End, Exporter of Titanium Alloy Gr 2 Elbow. Buy Certified & Tested Titanium UNS R50400 Seamless Pipe Fittings, Alloy Gr 2 Eccentric Reducer.

| UNS: |

R50400 |

|

Specifications: |

ASME SB-363 |

|

international Specifications: |

W. NR. 3.7035, W. NR. 3.7034 |