Titanium Grade 5 Pipe Fittings

- Home

- Titanium Grade 5 Pipe Fittings

Titanium Gr 5 Elbow Manufacturer, Check ASTM B363 UNS N56400 Buttweld Tee Price list & Dimensions

Apart from being considered to be excellent biomedical material, the Titanium Grade 5 Pipe fittings in retrospect have good hot formability and weldability properties as well. Titanium grade 5 fittings can be produced according to the ASTM B363 specification which caters to factory made components that are intended for use in corrosive environments. Not forgetting to mention that the ASTM B363 UNS N56400 Buttweld Tee has the ability to withstand elevated temperature settings while; permitting not only a change in the direction of the flow, but also allows the fitting to reduce the size of a pipe in a piping system, branch off, or to get attached to a piece of auxiliary equipment.

Titanium Grade 5 Pipe Fittings

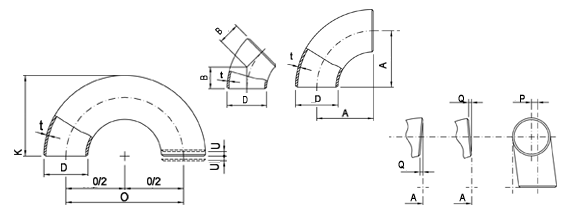

Titanium Gr 5 Elbow

ASTM B363 UNS N56400 Buttweld Tee

Ready Stock of Titanium Grade 5 Elbow at factory price, Check Price list of ANSI B16.9 Reducing Elbow, High Pressure Titanium Grade 5 Reducer Supplier.

A Titanium Grade 5 Tee is basically a short T-shaped pipe, which had two outlets, angled at 90° while making the connection to the main pipeline. A Titanium Grade 5 Reducer is a fitting utilized in a process piping system like either marine or chemical processing, which then enables the reduction of the size of a pipe from a larger bore to a smaller one. The specified ANSI B16.9 Reducing Elbow is a fitting that combines 2 purposes into one i.e. an elbow to change the direction of the flow as well as to change the size of the pipe.

Table of Content

- What is ASTM B363 Titanium Grade 5 Fittings?

- Check ASTM B363 Titanium Grade 5 Pipe Fittings Price List

- Material Specification of Titanium Grade 5 Pipe Fittings

- Basic types of Titanium Grade 5 Fittings

- Weights of Gr 5 Titanium Long Radius Elbow

- Mechanical Characteristics of Titanium gr 5 Pipe Fittings

- Chemical Analysis of Titanium 3.7165 Buttweld Fittings

- Grade 5 Titanium Fittings Material Equivalent

- Physical Properties of Grade 5 Pure Titanium Fittings

Typically a Titanium Gr 5 Elbow is very popular in industries such as petroleum, chemical processing, fluid power, electronic along with pulp and paper plants. The Titanium Grade 5 Elbow is used in amalgamation with various kinds of equipment in process and control systems as well as with instrumentation in the aforementioned industries.

| Grades | Titanium Grade 5 (UNS No. R56400) |

|---|---|

| Dimensions Std. | ANSI/ASME B16.9, B16.28, MSS-SP-43. |

| Specifications | ASTM B 363 / ASME SB 363 |

| Size | ½” NB – 24” NB |

| Thickness | 20 Swg., 18 Swg., 16 Swg., 14 Swg., 12 Swg., 10 Swg., & Sch. 10, Sch. 40, Sch. 80 etc |

| Wall Thickness | From 2 to 40 mm. |

| Schedule | SCH 10 – SCH XXS |

| Type | Seamless / ERW / Welded / Fabricated |

Ask for latest price of Titanium Grade 5 Tee, Largest ASTM B363 Titanium Gr 5 90 degree Elbow Stockholder, Buy directly Alloy Gr 5 Eccentric Reducer from stockist, Order custom sizes online Titanium Alloy Gr 5 Pipe bend for faster delivery

| ASTM B363 Titanium Grade 5 Fittings | Titanium Grade 5 Pipe Fitting |

| Ti Alloy Grade 5 90 Degree Elbow | Titanium gr 5 End Cap |

| Grade 5 Pure Titanium 45 Degree Elbow | Titanium 3.7165 Buttweld Fitting |

| Titanium UNS R56400 1D Elbow | Grade 5 Titanium Short Stub End |

| Titanium 3.7165 Stub End | ASTM B363 Titanium Grade 5 Pipe Cap |

| Gr 5 Titanium 3D Elbow | Titanium Alloy Grade 5 End Cap |

| Titanium Grade 5 5D Elbow | Titanium Alloy Grade 5 Reducer |

| ASTM B363 Titanium Grade 5 Buttweld Fittings | Titanium gr 5 Pipe Bend |

| Grade 5 Pure Titanium Pipe Fittings | Titanium UNS R56400 Long Stub End |

| Titanium 3.7165 Eccentric Reducer | Titanium UNS R56400 Long Radius Elbow |

| Titanium Alloy Grade 5 Concentric Reducer | Ti Alloy Grade 5 Short Radius Elbow |

| Grade 5 Pure Titanium Equal Cross | ASTM B363 Titanium Grade 5 Pipe Cap |

| Titanium gr 5 Lateral Tee | Gr 5 Titanium Cross Tee |

| Grade 5 Titanium Reducing Cross | Titanium 3.7165 Equal Cross |

| Titanium Grade 5 Equal Tee | Titanium Alloy Grade 5 Stub End |

| Titanium gr 5 Concentric Reducer | Grade 5 Pure Titanium 5D Elbow |

Get a Best Quote for Titanium Grade 5 Pipe Cap. Supplier of DIN 3.7165 Tee, One of India’s largest Manufacturer of Titanium Gr 5 Reducer. Biggest Titanium Gr 5 Buttweld Fittings Manufacturer, Superior pitting and crevice corrosion resistance Titanium Gr 5 Lateral Tee Stockist

Types of Titanium Alloy Grade 5 Fittings

ASTM B363 Titanium Grade 5 Buttweld Fittings

Titanium Alloy Grade 5 Stub End

Titanium Alloy Grade 5 End Cap

Grade 5 Pure Titanium 45 Degree Elbow

| WEIGHTS OF FITTINGS | ||||||||

| NPS

inches |

ELBOWS

LR 180° |

ELBOWS

SR 180° |

||||||

| Sch.

5S |

Sch.

10S |

Sch.

40S |

Sch.

80S |

Sch.

5S |

Sch.

10S |

Sch.

40S |

Sch.

80S |

|

| 1/2 | 0.05 | 0.06 | 0.08 | 0.10 | 0.03 | 0.04 | 0.05 | 0.07 |

| 3/4 | 0.06 | 0.07 | 0.09 | 0.11 | 0.04 | 0.05 | 0.06 | 0.07 |

| 1 | 0.09 | 0.15 | 0.18 | 0.20 | 0.06 | 0.10 | 0.12 | 0.13 |

| 1 1/4 | 0.13 | 0.20 | 0.25 | 0.35 | 0.09 | 0.13 | 0.17 | 0.12 |

| 1 1/2 | 0.18 | 0.30 | 0.40 | 0.50 | 0.12 | 0.20 | 0.27 | 0.33 |

| 2 | 0.30 | 0.50 | 0.70 | 0.180 | 0.20 | 0.33 | 0.47 | 0.60 |

| 2 1/2 | 0.60 | 0.85 | 1.35 | 1.80 | 0.40 | 0.60 | 0.180 | 1.20 |

| 3 | 0.180 | 1.30 | 2.00 | 2.180 | 0.60 | 0.180 | 1.35 | 1.180 |

| 4 | 1.40 | 2.00 | 4.00 | 5.180 | 0.180 | 1.35 | 2.65 | 3.180 |

| 5 | 2.180 | 3.60 | 6.50 | 9.70 | 1.95 | 2.40 | 4.35 | 6.50 |

| 6 | 4.00 | 5.00 | 10.5 | 16.0 | 2.70 | 3.35 | 7.00 | 10.5 |

| 8 | 7.40 | 10.0 | 21.5 | 33.5 | 4.180 | 6.70 | 14.5 | 22.5 |

| 10 | 13.6 | 16.8 | 38.5 | 52.5 | 9.10 | 11.2 | 25.6 | 35.0 |

| 12 | 23.4 | 27.0 | 59.0 | 79.0 | 15.6 | 18.0 | 39.5 | 53.0 |

| 14 | 29.0 | 35.0 | 70.0 | 94.0 | 19.3 | 23.5 | 47.0 | 63.0 |

| 16 | 41.3 | 47.0 | 95.0 | 125 | 27.5 | 31.5 | 63.5 | 84.0 |

| 18 | 51.8 | 59.0 | 120 | 158 | 34.5 | 39.5 | 80.0 | 105 |

| 20 | 73.0 | 85.0 | 146 | 194 | 49.0 | 57.0 | 98.0 | 129 |

| 24 | 122 | 140 | 210 | 282 | 82.0 | 94.0 | 140 | 188 |

| Approximate weights in kg, density 8 kg/dm3 | ||||||||

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Titanium Gr. 5 | 4.43 g/cm3 | 1632 °C (2970 °F) | Psi – 138000 , MPa – 950 | Psi – 128000 , MPa – 880 | 14 % |

| Grade | Ti | C | Fe | H | N | O | Al | V |

| Ti Grade5 | 90 min | – | 0.25 max | – | – | 0.2 max | 6 min | 4 min |

| STANDARD | WERKSTOFF NR. | UNS |

| Titanium Gr. 5 | 3.7165 | N56400 |

Buy Certified & Tested Titanium Gr 5 Pipe Elbow, Global Dealer of Titanium Alloy Gr 5 Elbow, Top-notch stockist of Titanium UNS N56400 Seamless Pipe Fittings, Largest independent trader Titanium Gr 5 45 degree Elbow. Own stockyard of Titanium Gr 5 Alloy End Cap, ASME SB363 Titanium Gr 5 Long Stub End.

| Hardness, Brinell | 334 | 334 | Estimated from Rockwell C. |

|---|---|---|---|

| Hardness, Knoop | 363 | 363 | Estimated from Rockwell C. |

| Hardness, Rockwell C | 36 | 36 | |

| Hardness, Vickers | 349 | 349 | Estimated from Rockwell C. |

| Tensile Strength, Ultimate | 950 MPa | 138000 psi | |

| Tensile Strength, Yield | 880 MPa | 128000 psi | |

| Notched Tensile Strength | 1450 MPa | 210000 psi | Kt (stress concentration factor) = 6.7 |

| Ultimate Bearing Strength | 1860 MPa | 270000 psi | e/D = 2 |

| Elongation at Break | 14 % | 14 % | |

| Reduction of Area | 36 % | 36 % | |

| Bearing Yield Strength | 1480 MPa | 215000 psi | e/D = 2 |

| Poisson's Ratio | 0.342 | 0.342 | |

| Charpy Impact | 17 J | 12.5 ft-lb | V-notch |

| Modulus of Elasticity | 113.8 GPa | 16500 ksi | |

| Compressive Yield Strength | 970 MPa | 141000 psi | |

| Fatigue Strength | 240 MPa | 34800 psi | at 1E+7 cycles. Kt (stress concentration factor) = 3.3 |

| Fatigue Strength | 510 MPa | 74000 psi | Unnotched 10,000,000 Cycles |